A “technology breakthrough” in specialist-application turning and boring tooling was shown by Sumitomo Electric Hardmetal Ltd (

www.sumitomotool.com); its development team has created a highly wear-resistant nano-polycrystalline diamond indexable insert that is harder than single-crystal diamond and can finish-turn exceptionally hard brittle materials such as cemented carbide, silicon carbide and tungsten-carbide cobalt (WC-Co) — as used in punches and dies. Previously, these could only be machined by grinding.

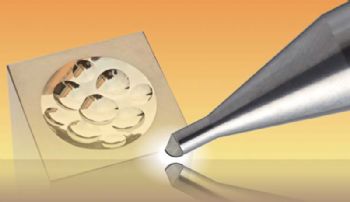

The Sumidia Binderless NPD10 grade of insert is a polycrystalline isotopic diamond, whereby the manufacturing process directly combines very fine (tens of nanometre) diamond particles together without the use of a binder (at the grain boundaries) that could be degraded or fail at high temperatures.

Sumitomo says typical uses include the machining of carbide dies and cutting tools, as well as processes involving ‘difficult materials’ used in the medical, nuclear, instrument, military (such as armour-piercing components) and jewellery.

When external-turning a 50mm-diameter x 30mm-long carbide die, the machine was run (dry) at 20m/min with a feed of 0.1mm/rev and 0.1mm depth of cut.

When finish-boring a carbide die with an NPD10 insert, the nominal 8mm profiled bore size was machined at 15m/min, 0.015mm/rev and 0.07mm depth of cut.

Sumidia Binderless NPD10 inserts are available in negative and positive styles of square, triangular, diamond and trigon shapes.