#MACH2018 Partnership arrangements with machine tool manufacturers, along with considerable interest in its new Designer CAD for CAM system, were highlights of Vero Software’s participation in

MACH (

www.verosoftware.com).

The company had a total of 18 ‘partner hot-spots’ around the show, with its Edgecam CAM software used to program 12 CNC machines on nine manufacturers’ stands to demonstrate five-axis simultaneous machining, Waveform turning and milling, mill/turning, wire EDM and ‘certified posts’.

For example, DMG Mori ran Edgecam on a DMU 60 Evo Linear machine with a five-axis simultaneous program, and an NTX 2000 for mill/turning operations.

UK showroom manager Christopher Cooper said: “The linear machine is especially dynamic, moving at 80m/min. We created an impeller from an aluminium block, using Edgecam to produce code that would show the machine’s full capabilities, moving the part around and removing material in the most efficient way.”

Matsuura also programmed two machines with Edgecam for mill/turn and five-axis operations. The company said: “Visitors to our stand were particularly impressed with how Edgecam produced a highly complex part that looks like a puzzle or optical illusion.

"It was challenging to program, but Edgecam took programming our MX 330 in its stride. We work very closely with Edgecam to ensure that customers get the very best out of their machine tools. ”

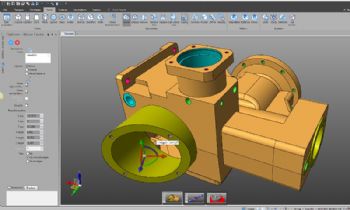

Edgecam also reported considerable interest in the new Designer module — a direct modelling system that fills the gap between CAD and CAM, focusing on the specific needs of machinist programmers.

It allows users to create new designs or modify existing geometry from third-party CAD systems.

Moreover, it is not dependent on having a series of parameters to drive it, or a feature tree; it provides a quick, dynamic editing and modelling environment that allows users to sketch, drag, hold, push or twist to create and modify models.

Edgecam engineer Mike O’Neill said: “We also demonstrated the new Edgecam 2018 R2. What particularly caught customers’ attention were the auto Plunge Drill function in the roughing cycle, which automatically creates the hole position and keeps the drilling tool-path associative to the cycle, and the ability to create a new feature from the wireframe command.”

As well as Edgecam, Vero also demonstrated VISI, Radan, WorkXplore and its ERP systems, generating strong leads from increased footfall over the previous

MACH.

Radan’s senior applications engineer, Bob Thorne, said visitors expressed considerable interest in the sheet-metal software’s logistics package, which includes RadPro, RadQuote and RadManager.