According to a report in

Space News, Made In Space — the Silicon Valley start-up focused on additive manufacturing in space — plans to boost the power available to small satellites with its Archinaut in-space manufacturing and assembling technology.

Chief executive Andrew Rush said: “Small satellites have solar panels that produce 1-1.5kW of power; we can achieve 4-5kW.”

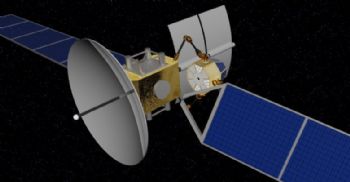

Made In Space proposes launching a 150-300kg satellite with a “tightly packed solar-cell blanket” and raw material to feed an onboard 3-D printer that will manufacture solar arrays optimised for use in microgravity, when the satellite is in orbit.

The solar arrays built on Earth and sent into space are reinforced to withstand launch forces, stowed to fit into the launch vehicle and equipped with mechanisms to deploy them in orbit, but the Archinaut solar arrays would be designed for microgravity.

Some emerging ‘small-sat’ applications, from remote sensing to communications, require more power than the solar cells on small-sats typically provide.

With Archinaut, Made In Space plans to give satellite developers a way to equip small satellites with solar arrays up to 20m

2.

In 2016, NASA’s Space Technology Mission Directorate awarded Made In Space and its partners (Northrop Grumman and Oceaneering Space Systems) a two-year $20 million contract to develop Archinaut.

The award was made through NASA’s Tipping Point programme, which funds space technologies that promise significant benefits for government and commercial customers through public-private partnerships.

Mr Rush said Made In Space is seeking a follow-on contract for an in-orbit demonstration of its Archinaut technology.

The company sent its first 3-D printer to the International Space Station in 2014, followed by a second printer (known as the Additive Manufacturing Facility) in 2016.