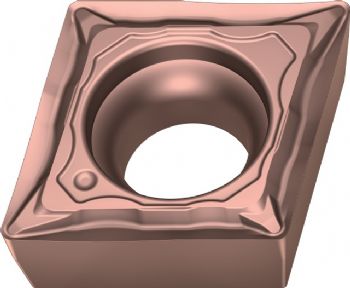

Two major advantages over coated carbide inserts for finish turning are claimed by Birmingham-based Walter GB Ltd (

www.walter-tools.com) for its new WEP10 cermet indexable inserts: double the tool life and no fluctuation in dimensional wear.

Made from an extremely fine-grained substrate on a TiCN/CN base with an Ni/Co binder, the benefits are a result of the insert’s highly wear-resistant multi-layer coating.

In addition, a special edge preparation on the cermet grade produces a ‘glossy’ finished surface — at both high and low cutting speeds.

This premium finish is particularly desirable for components that are visible, such as those used in car interiors, for which a ‘good’ finish is not enough.

WEP10 is suitable for machining stainless steels and cast iron, as well as ISO P materials. It can also be applied for finishing parts such as drive shafts and gear-wheels with a continuous or slightly interrupted cut.