Yamazaki Mazak’s traditional November Open House — 20-22 November at Mazak’s European Technology Centre in Worcester — will feature a “star-studded” cast of machines, as well as guest speakers, tours and live machining demonstrations.

The theme of the event is manufacturing excellence, and it aims to give attendees a comprehensive overview of the latest machining technologies, as well as laser, additive manufacturing, machine connectivity and sector specialisation (

www.mazakeu.co.uk).

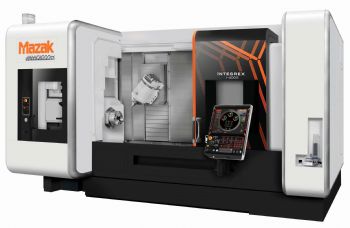

One of the 20 machines on display will be an Integrex i-400S machining centre, which is equipped with Mazak’s SmoothX CNC and designed for applications in a range of industry sectors, including aerospace and automotive.

This machine features Mazak’s new SMOOTH Gear Cutting software, which combines advanced multi-tasking machining with gear manufacturing processes; these include gear skiving, gear milling and gear hobbing.

The software allows the operator to develop complex gear machining programs easily by entering the gear data via a user-friendly dialogue on the CNC, further reducing set-up times.

Also being demonstrated will be a VCN-530C, a European-built vertical machining centre powered by a newly designed 12,000rev/min milling spindle; it also features ballscrew cooling on the X, Y and Z axes, Mazak’s Intelligent Thermal Shield to ensure stable machining accuracy, feed rates up to 42m/min and a chip-to-chip time of 2.8sec.

Meanwhile, the new direct diode laser (DDL) version of Mazak’s FG machine range (one of three laser machines on display) will be making its UK debut.

The DDL is is designed for cutting both thin and thick materials, as well as highly reflective materials such as copper and brass. It also features a new 3-D head with an independent Z axis and tapping units.

Five-axis machining will also be featured, with the Variaxis i-300 AWC (Auto Work Changer) simultaneous machine developed specifically for the high-mix low-volume demands of sectors such as medical and aerospace.

The AWC system accommodates 32 work-holders as standard and allows unmanned running.

Alan Mucklow, managing director UK and Ireland Sales at Yamazaki Mazak, said: “This year’s event, which is focused on how machine users can develop manufacturing excellence, is very much a combined laser and machine tool Open House with partners from both areas supporting it.

“I am delighted to be displaying a range of outstanding technologies, alongside a number of guest speakers who will share their own experiences of using different technologies and offer a glimpse into the future of manufacturing.”