Hove-based CGTech will demonstrate how advanced programming strategies and simulation can lead to better composite parts at the

2019 JEC Composites show (Hall 5 Stand Q49), taking place 12-14 March at the Paris Nord Villepinte Exhibition Centre in France.

The company (

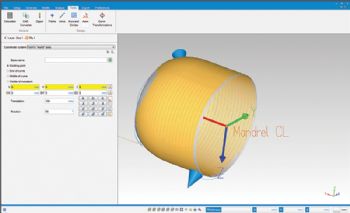

www.cgtech.co.uk) will also showcase Composites V8.1.2, the latest version of Vericut Composite Programming (VCP) and Vericut Composite Simulation (VCS).

The Composites V8.1.2 release of VCP and VCS features a completely redefined Graphical User Interface, an enhanced suite of programming and analysis tools, and redefined methodology through the use of the powerful new Laminate Manager.

This new tool helps users to manage files, processes and batch actions for the entire composite laminate. Internal refinements ensure that large projects can now be programmed and simulated in a fraction of the previous time.

The aerospace industry continues to push for lighter, faster and more cost-effective parts. With more information available than ever before, part programmers can generate and export part statistics directly from VCP.

The addition of the all-new summary reports allows engineers to compare different layup strategies and feel confident that the optimal design prevails. “However, one should not stop at the programming stage,” says Tony Shrewsbury, CGTech Ltd managing director, “companies now more than ever are realising the importance of simulation and the digital twin model.

"With VCS, users can watch their parts come to life on their machine, leaving them confident that the intended design will match what is manufactured.”

Vericut 8.2 is a leading CNC machine simulation, verification and optimisation software that enables users to eliminate the process of manually proving out NC programs.

It simulates all types of CNC machining, including drilling and trimming composite parts, water jet, riveting, robotics, mill/turning and parallel kinematics. The software runs ‘stand-alone’, but it can be integrated with leading CAM systems.