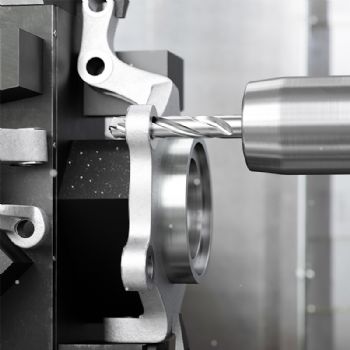

Two new drills optimised for drilling aluminium automotive parts have been developed by cutting-tool and tooling-systems specialist Sandvik Coromant (

www.sandvik.coromant.com).

Designed for machining components in medium-to-large volumes, CoroDrill 400 and CoroDrill 430 deliver high throughput and low costs, as well as extended tool life and enhanced process security.

Moreover, these drills complement CoroTap 100, 200, 300 and 400, which are also optimised for tapping operations in ISO N material, and help to provide a complete hole-making offer.

While both CoroDrill 400 and CoroDrill 430 are available in the Sandvik Coromant N1BU solid-carbide grade, the former can also be specified in the new N1DU ‘veined’ poly-crystalline diamond (PCD) grade (N1DU provides PCD across the entire cutting edge, thus offering much longer tool life).

Due to PCD’s low coefficient of friction and high conductivity of heat, the tool’s cutting edges are less susceptible to built-up edge).

CoroDrill 400 is recommended for drilling into solid material, as it features more flute volume for better chip evacuation.

When drilling into cored material or pre-cast holes, CoroDrill 430 will perform better, as it features three flutes for increased stability and holding true position — regardless of misaligned cored holes.

CoroDrill 400 and CoroDrill 430 feature polished flutes and precision coolant holes; they also support MQL (minimum-quantity lubrication).

They are available as standard in diameters of 5, 6.8, 7, 8.5, 10.2 and 12.5mm, which correspond to M6, M8, M10, M12 and M14 thread sizes. Tailor Made options can also be specified for other applications.