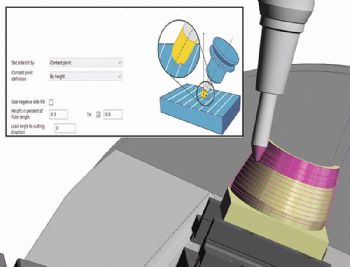

The introduction of a specific

five-axis ‘Tilt’ control strategy, combined with a ‘Barrel Cutter,’ is said to be the most significant enhancement in the latest release of Edgecam from Hexagon Manufacturing Intelligence’s Production Software division (

www.HexagonMI.com).

Brand manager John Buehler says barrel cutters are recognised as one of the fastest tools when five-axis machining, and they are now fully supported in the Edgecam Toolstore; and as well as the new ‘side tilt by contact point’ capability, the latest five-axis cycle also offers further gouge checking in the ‘Swarf’ command.

A number of new and enhanced features in Edgecam 2020.0 provide increased productivity for both milling and turning operations.

Included is a significant performance boost when either roughing or profiling a solid model.

Formerly introduced in the Hole cycle in the 2018 R1 release, the ‘Deep Hole’ strategy has been enhanced with the addition of further ‘control tabs’ to give greater control over the tool-path.

For turning, there is a new machining cycle — Thread Profiling — that simplifies the machining of complex-form threads such as VAM and Acme, while the Waveform machining strategy has been enhanced with ‘Chip Prevention’

control.

To support the growing number of machine tools with an ‘auxiliary Z’ (quill), Edgecam 2020.0 features a ‘Code Wizard’ that lets users add a secondary spindle and thereby support multi-tasking machines, as well as “any combination of table/head milling machines”.

Meanwhile, when using the Finish Grooving cycle, users can now control the ‘break edge’ angle (in previous releases, the break angle was set at 45deg); and in the ‘Finish Turning’ cycle a ‘stand off’ value can now be defined when using ‘up cut’ control.

Furthermore, an XY offset can be set when using the Hole Cycle’s ‘Helical’ strategy, thereby allowing users to control both surface finish and tool wear.

With regard to the Edgecam Inspect module, this now includes 13 upgrades.

The overall interface has been upgraded to adopt the work-flow ribbon tool-bar for improved interactivity, and the ‘Probing Options’ menu has been split into two separate dialogs so that users can concentrate on ‘Output and Inspect’ preferences individually.

Furthermore, ‘safe retract’ controls have been added to the inspection cycles, allowing users to state multiple positions while controlling the probe’s movement; and the ‘Index’ command now offers further ‘positional manipulation’ (an alternative angle can be specified in order to view the components on the machine tool).