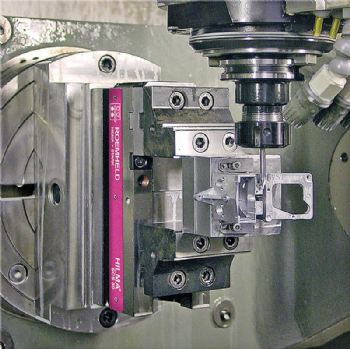

New, compact work-holding systems designed to accommodate metal-cutting operations on five-axis machining centres have been introduced by Hitchin-based Roemheld UK Ltd (

www.roemheld.co.uk).

They are manufactured by the German group’s Hilma division in Hilchenbach.

The fixed-jaw SCS vice allows good accessibility of tools to the component, enabling five-sided machining without collision when using short standard tools — thereby lowering costs and improving workpiece accuracy due to less vibration.

Moreover, stability of the clamping systems and high retention force resulting from the use of a reversible jaw mean that there is no need to pre‐stamp a workpiece before it is secured, even when it is clamped on just a few millimetres of material — and the repeatability of positioning is to within ±10µm.

Manufactured to high levels of accuracy, SCS work-holding systems feature high levels of stability; and by offering comprehensive swarf protection, they can be used in multi-pallet prismatic machining cells.

Operation is either mechanical (via a threaded spindle and torque wrench) or via a single-acting hydraulic cylinder to effect the clamping pressure, with unclamping achieved by spring force.

Various base lengths up to 350mm are offered, with different clamping ranges to 300mm; clamping force is up to 40kN at 100Nm.

An extensive range of hardened-and-ground jaws (as well as soft jaws) in 80 and 120mm widths is available, to suit the various vice models.

Customised versions in other lengths or with individual mounting holes — including those for zero-point clamping — are also available.