Welding technology specialist K-TIG has become a member of the Rotherham-based Nuclear AMRC in order to develop new high-performance fabrication techniques for waste containers and other nuclear-industry applications.

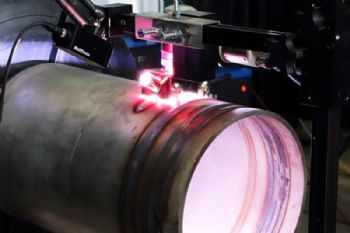

Based in Australia, K-TIG has developed a patented keyhole welding technology that can produce welds 10- to 100-times quicker than conventional tungsten gas arc welding, joining metals up to 16mm thick in a single pass.

This technology is already in operation with some of the world’s largest fabrication businesses, and it is also accessible to small and medium-size manufacturers.

The Nuclear AMRC has worked with K-TIG to assess and develop the technology for nuclear-industry applications since 2015, with recent research focusing on waste containers made of duplex stainless steel.

By joining the centre as a Tier Two member, K-TIG will deepen its partnership with the Nuclear AMRC to help manufacturers in the UK decommissioning supply chain improve their productivity and reduce their costs for waste container fabrication.

Neil Le Quesne, K-TIG president (market development) (

www.k-tig.com), said: “The Nuclear AMRC’s approach to developing highly advanced manufacturing techniques and processes for the benefit of the nuclear sector through industry partnerships with leading technology providers is unrivalled globally.

"K-TIG intends to build on the last several years of collaboration to become a long-term partner and to collaborate extensively in solving the productivity challenges associated with fabricating the tens of thousands of nuclear storage containers required by the UK nuclear decommissioning programme over the coming years.

"The Nuclear AMRC’s focus on exceptional weld quality, negligible distortion, high corrosion resistance and stable material properties under the most demanding conditions is the identical focus as K-TIG’s, and we look forward to co-developing solutions that will deliver highly tangible commercial outcomes.”