The installation of a new

Trumpf TruLaser Tube 3000 fiber at Salisbury-based

Lasercell in August last year has enabled the company to bring all its tube laser cutting requirements in-house. Alongside the associated reduction in lead times, Lasercell’s new capability means the company can now design parts more efficiently.

Lasercell was founded in 2012, initially focusing on architectural sheet metalwork with a flat-bed laser. However, the company soon became an established sub-contractor in the region, supplying sectors such as shopfitting, marine and general engineering, and has grown into a 25-employee business.

Kieran Bernstein, one of three company directors, said: “Primarily we are a laser profiling sub-contractor of both sheet and now tube. It provides a good balance — a fairly even split — with the other side of our business, architectural metalwork. From a sub-contract perspective we take on almost anything, although we tend to pick up a lot of thinner gauge laser work in attractive metals such as brass, copper and stainless steel.”

Impressive growth over the past decade prompted Lasercell to investigate the potential for an in-house tube laser cutting capability. Mr Bernstein explained: “Not only would a tube laser eliminate the cost of outsourcing, it would allow us to design some of our architectural metalwork differently. Previously, if we had an urgent job, we would have to design folded profiles for features that would normally lend themselves to box section, just so we could produce it quickly in-house using our flat-bed laser and press brakes. By investing in a tube laser we have made it a lot easier and more efficient for ourselves in terms of design and how we join parts together.”

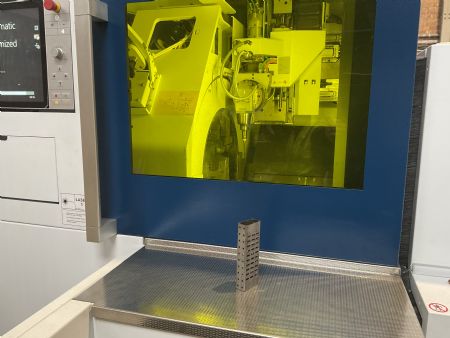

Lasercell looked at a few major manufacturers of tube laser machines before drawing up a shortlist of two. After a comprehensive assessment, the company opted for the Trumpf TruLaser Tube 3000 fiber, a machine that can accommodate tube diameters up to 152mm and process mild steel up to 8mm thick, stainless steel and aluminium up to 6mm, and copper and brass up to 4mm.

Enormous growthThe 3kW machine installed by Lasercell, which is the first of its type in the UK, includes a 3-D cutting head and LoadMaster Tube automation with bundle space for up to 4 tonnes of unprocessed material. Trumpf has seen enormous growth in tube laser demand over the past few years, prompting the company to expand its machine portfolio and associated software offer.

Mr Bernstein said: “Perhaps the most influential reason behind our choice was Trumpf’s Programming Tube 3-D software, which was superior to that of the other potential supplier. With Programming Tube, we quickly and intuitively create NC programs. The software offers flexible data import procedures and efficient design, with step-by-step support.”

The Trumpf TruLaser Tube 3000 fiber laser is currently busy serving both sides of Lasercell’s business: architectural metalwork and general sub-contracting. On a day-to-day basis, the machine processes mild and stainless steel box, angle and tube, as well as brass and aluminium, typically in thin gauge and small diameter material. Occasionally, however, the company will process material up to 5 or 6mm thick.

Mr Bernstein continued: “Although we have been really busy, the machine is so quick that keeping it fed can sometimes be a challenge. As well as eliminating the need to outsource our tube laser work, reducing lead times and designing parts more efficiently, the new machine gives us a unique selling point when promoting our services. We like to help our customers with their design for manufacture requirements and the tube laser plays a big part in that offer.”

Along with laser cutting and bending, Lasercell offers welding, assembly, polishing, powder coating and galvanising, as well as specialist services such as 3-D CAD design, rapid prototyping and even site installation.

Mr Bernstein concluded: “Quality, speed and understanding are what set us apart from our competitors. We have a lot of engineering knowledge — it is not simply about taking what the customer gives us, it is what we can offer them in return. Our aptitude in problem solving is what brings our customers back.”

With business currently flourishing, Lasercell intends to continue investing in both technology and people — the company recently recruited five new members of staff.