UK-based

PTG Holroyd has announced that all models in its TG Series of ultra-precise helical rotor and thread grinding machines will now be equipped with the

Siemens digitally native Sinumerik One CNC as standard.

PTG Holroyd was the first UK-based machine tool manufacturer to embrace the benefits of the Sinumerik One CNC, incorporating the control system into its recently launched HG350 range of worm and gear grinding centres. The decision to roll out the CNC into its latest-generation TG series machines is a clear indication of the company’s desire to future-proofing its technologies.

Mark Curran, PTG Holroyd sales director, said: “The Sinumerik One CNC has brought significant user benefits to our HG350 machines, including class-leading integrated safety and failsafe features, enhanced reporting of machine health and performance data, and uncompromising levels of encrypted security. Factor in the high levels of support we receive from Siemens, and it seemed only sensible to migrate to the Sinumerik One for our TG series of rotor and thread grinding machines.”

PTG Holroyd’s TG series is widely regarded as setting the industry standard for high-speed, high-accuracy, efficient stock removal. With the inclusion of the Sinumerik One CNC, the machine tool manufacturer believes its TG range of helical rotor and thread grinding machines will be even more attractive to its global customer base. Enhanced connectivity is provided via additional Profinet interfaces, OPC/UA interfaces and increased performance — all made possible thanks to a PLC that is 10-times faster than earlier Siemens controls.

While from a machine tool manufacturing perspective, using the CNC’s Create MyVirtual Machine capabilities, in tandem with its own internal design packages, will enable PTG Holroyd’s design teams to develop all software and PLC controls on the desktop. Mr Curran added: “Just as with our HG range, this will reduce lead times significantly, avoiding the need to have the physical machine on the shopfloor before commencing software development.”

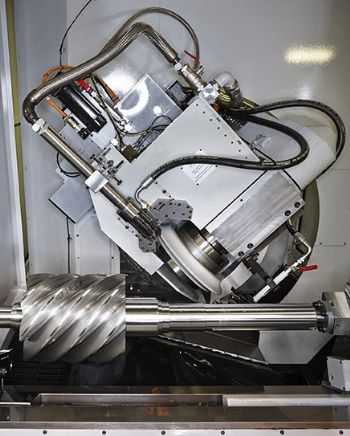

Equally suited to prototyping, batch and volume production, PTG Holroyd’s TG series machines are designed primarily for the finish grinding of helical screw components such as worm screws and rotors after they have been milled to a rough or semi-finished state.

The TG range starts with the TG50E (pictured), a machine designed to precision grind components of up to 50mm in dia and 610mm in length, with models offering stepped increases in capability up to the production of helical components measuring 450mm in dia and 2,020mm in length. Each machine’s advanced automation means reduced set up time, while a significant amount of production time can be saved due to the fact that diamond dressing discs are continuously dressed during the semi-finish grinding cycles.

TG models offer production rates and accuracies to suit precise manufacturing strategies. Fully automated on-machine probing provides closed loop feedback of corrections to the dresser wheel and does not require a high level of operator skill.