Wakefield-based

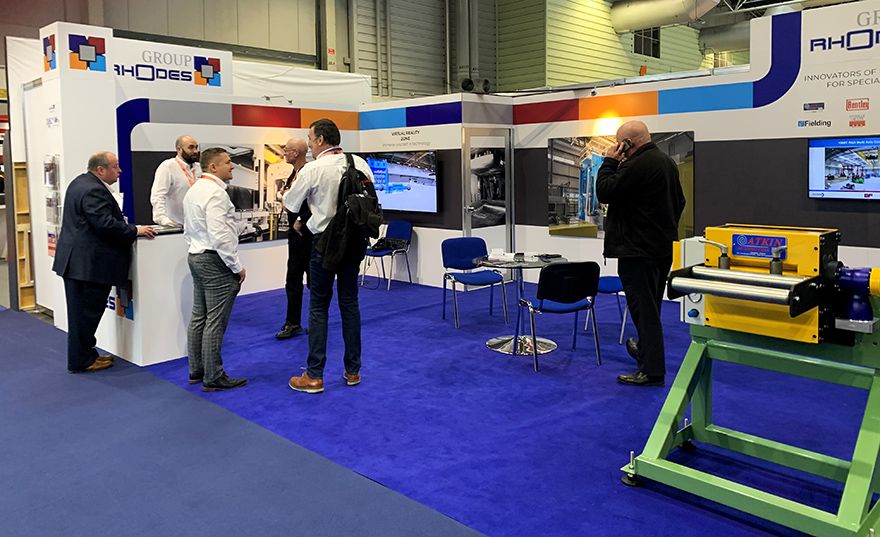

Group Rhodes, a leading manufacturer of metal and composite forming machinery, will be demonstrating one of its innovative bespoke metalforming presses within the MMMA Metal Working Village at

MACH 2024, which is taking place 15-19 April at the NEC, Birmingham (Hall 6, Stand 599).

The Rhodes Interform product on display was designed and manufactured in-house at the company’s factory as part of a full turnkey solution to produce a bespoke twin press facility for forging forklift truck components. The entire project, which consists of two Rhodes Interform multi-axis presses, a complete robotic handling line and an integrated conveying system, is capable of processing the largest forks at a rate of one part every 70sec.

Group Rhodes will also be discussing the global patents it has registered for its industry-leading Superplastic Forming and Diffusion Bonding Technology (SPF/DB), including the territories of China, India, the USA and Europe. This innovative solution is applied extensively to the lightweighting of components within the aerospace and automotive industries.

Operations director James Gascoigne said: “We are looking forward to attending

MACH 2024 which will give us the opportunity to demonstrate our latest innovations in metalforming technology. This will be our first exhibition since we secured international patents for Superplastic Forming and Diffusion Bonding and it will be a great chance for our team to discuss how these technologies works and their potential applications globally.”

He added: “Given that our 19th-century patents were for improvements to the steam hammer, it is amazing to think that our most recent innovations are helping to form components for spacecraft! We are very proud to showcase these innovations — especially in our 200th anniversary year.”

Alongside its SPF/DB technology, Group Rhodes’ highly knowledgeable engineers will be present on the stand to discuss the company’s extensive portfolio of machinery for the hot and cold forming of metals and composites.

Group Rhodes actively manufactures and markets its bespoke machinery from its facilities in Wakefield, which it sells to both the UK and global markets. The main divisions of the Group consist of Joseph Rhodes, Rhodes Interform, Craven Fawcett, Beauford Engineers, Rhodes Environmental, Slater & Crabtree and Hallamshire Engineering.