As well as giving UK exhibition debuts to new product lines, the

Kerf Developments stand at

MACH 2024, will have its largest-ever range of products on show (Hall 6, Stand 330), which is taking place 15-19 April 2024. The Rochdale-based manufacturer of oxy/fuel, plasma, waterjet and fibre-laser cutting machines, will be launching two new innovations at the show, which will be demonstrated with automated cutting and welding solutions supplied by technical partner Lincoln Electric.

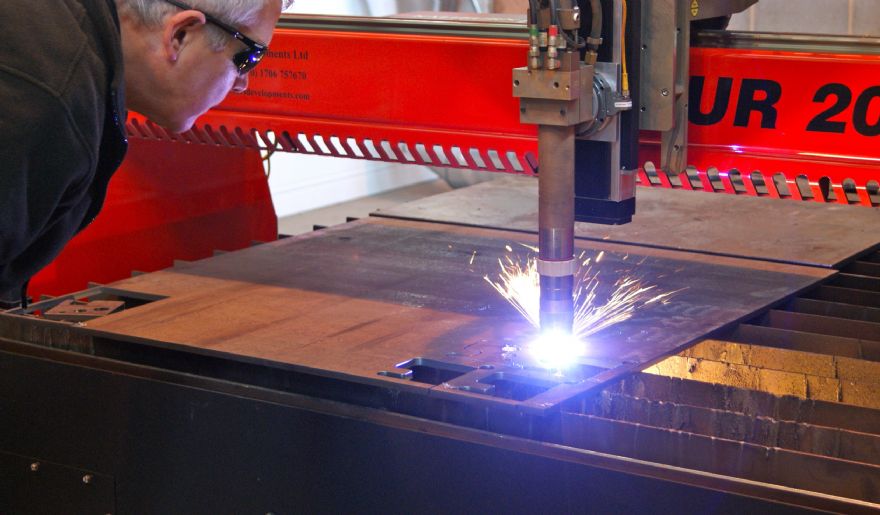

Taking centre stage will be the Kerf Ultra, which offers both oxy/fuel and plasma cutting in a single solution. This machine which combines both technologies, expands the cutting capabilities, flexibility and processing speed for end users while reducing set-up time and material changeovers. For customers of the longstanding industry-leading Kerf models, the new Ultra will be a technological leap forward that marks the arrival of the next generation of profile cutting technology. This innovation brings the performance, speed and precision of laser cutting to a plasma cutting platform for the first time.

With significantly improved speed, precision, repeatability and cut quality than previous models, the new Ultra features a new motion system and new linear slide technology that sits upon a brand new machine frame design. This combination of factors provides vibration-free cutting under the most challenging of conditions that subsequently delivers a remarkably smooth cutting motion and ultimately an unparalleled cut quality that eliminates secondary hand finishing.

From a specification perspective, the new machine that is designed around a solid fabricated portal frame using independent rails, can be offered in cutting table sizes from 3 x 1.5m, right the way through to 40 x 4m. The machine is controlled by a Burny 10 LCD Plus CNC control system and has a new heat-shielding system that extends the performance and longevity of the machine. The new arrival can be configured with UltraSharp plasma technology, as a single or multi-head oxy/fuel cutting machine or as a combination machine with both technologies supported on the same machine and is available in a range of widths and lengths to suit customers requirements. There is also a wide range of Lincoln Electric Fineline plasma units to choose from.

One feature of the new Ultra machine is the unique oxy/fuel automatic gas console (AGC) available from Kerf. This will help to address the skills shortage in the industry as the AGC replicates the skills and knowledge of an experienced machine operator using pre-programmed technology databases. Through digital proportional valves, this technology sets variables such as cut heights for piercing, low and high pre-heat gas pressures, and the pierce curve reducing spatter and blow back. The new AGC on the Kerf Ultra also reduces gas consumption, increases consumable life, improves cut quality and helps to de-skill the process for the machine operator.

The second new machine on display at

MACH 2024 will be the new Linc-Cut Fiber 1530A fibre laser system that is also new to the UK. More details on this machine will be made available closer to the show.

One thing that Kerf will be proud to discuss at

MACH is its partnership with Lincoln Electric, the world’s largest manufacturer of cutting and welding equipment. As an outright industry leader, the reputation of Lincoln Electric is unsurpassed in its field. At

MACH, Lincoln representatives will be available on the Kerf stand to present the latest Linc-Cobot system for collaborative robot (cobot) welding as well as demonstrating the Python X automated cutting technology alongside the Zeman automated beam-welding technology.