Spain-based

Lantek, a world-leading specialist in sheet metal CAD/CAM and ERP systems will be exhibiting its latest software releases at

MACH 2024, which is taking place 15-19 April at the NEC, Birmingham (Hall 17, Stand 319).

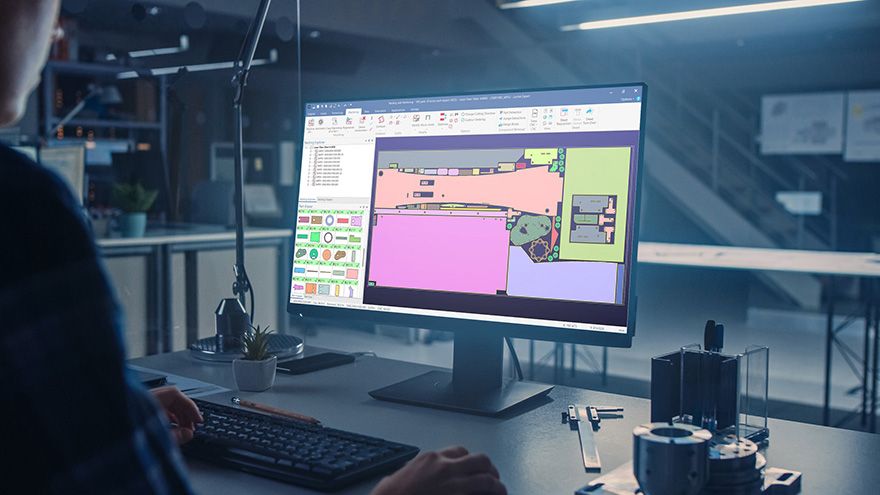

Flexibility is one of the major improvements in Lantek Expert, making it easy to move nests of parts between different machines as production requirements dynamically change, without the need for manual adjustments. Brand new is the ‘Assembly 2 Nesting software’ which enables customers to import a complete 3-D model assembly of parts. These are individually sorted and unfolded in the Lantek software, nested and then cut in the shortest possible time, without the user needing their own CAD system to do 3-D model manipulation.

For tube and pipe work, Lantek Flex3D has seen some fundamental enhancements which reduce execution times. The software also helps eliminate collisions through hole destruction technology and aims for a ‘no scrap’ target with micro joints connecting parts together to use up every bit of the tube material.

Lantek’s ‘Machine Connectivity’ makes it possible to directly connect to different machines, gathering information from the machine automatically. This data is fed into the Lantek Control Panel app which provides a cloud-based interface to monitor the cutting machine state irrespective of its type or technology, without operator intervention, in real-time. The app can be accessed on a tablet or mobile device so that the collected and merged data can be viewed by managers giving them a real-time overview of the complete production process and manufacturing facility. The app also displays utilisation rates so that free capacity can be allocated and, gives warnings when unexpected events occur, so that remedial action can be taken without delay.

Significant productivity improvementsAdam Ball, solutions sales manager for Lantek UK, said: “This technology is particularly useful for companies that use a mix of different cutting technologies such as punching, laser or waterjet from different manufacturers. The real time feedback will lead to significant productivity improvements, avoiding errors, cost overruns and will optimise the use of available machine capacity.”

The power of the Lantek software lies in the way in which it is integrated into the overall manufacturing and management processes within a sheet metal company. Accurate and fast quotations directly impact the levels of business won. Lantek has the tools to minimise the work involved in creating quotations, using stored, calculated and historic data on material prices, operation times and material usage with products including iQuoting, Assembly 2 Nest and Lantek Expert.

During production, Lantek Integra products including Lantek MES and Lantek WOS keep track of and monitor stock levels, material availability, capacity, delivery times and costs against targets, optimising the efficiency of the manufacturing process. The new Machine Connectivity tools further increase the accuracy, efficiency and automation of every aspect of this process.

Over 35 years of development have been put into optimising the software to exactly suit sheet metal manufacturing, giving Lantek the skills, knowledge and capability to maximise the efficiency and profitability of manufacturers.