As a company that has continually evolved over the last 40 years to become a leading force in composite and GRP development and manufacturing,

KS Composites is at the very cutting edge of innovation. The company operates in the motorsport, marine, energy, rail, aviation and defence sectors and the Melton Mowbray company relies upon the expertise of the cutting tool experts at

Industrial Tooling Corporation (ITC) to deliver results.

Working out of a 48,000ft

2 manufacturing facility that accommodates more than 100 staff, KS Composites services and facilities include everything from design and manufacture to FEA, CFD, kit cutting, wet clay composite shop, autoclaves and ovens, fitting and assembly and a modern machine shop. Some of the company’s recognised customers and projects include the Jaguar Project 8, Revolution Racecars and a multitude of prestigious F1 projects.

Dan Johnston, business development manager at KS Composites, said: “We use ITC cutting tools due to the great working relationship we have with the team and the longstanding first-rate service we receive. Whether discussing new advancements in tooling technology or looking at building up a package of tools to support a project, ITC has always given us great advice. Even better is the on-site support in running tooling trials to confirm that tooling works as stated.”

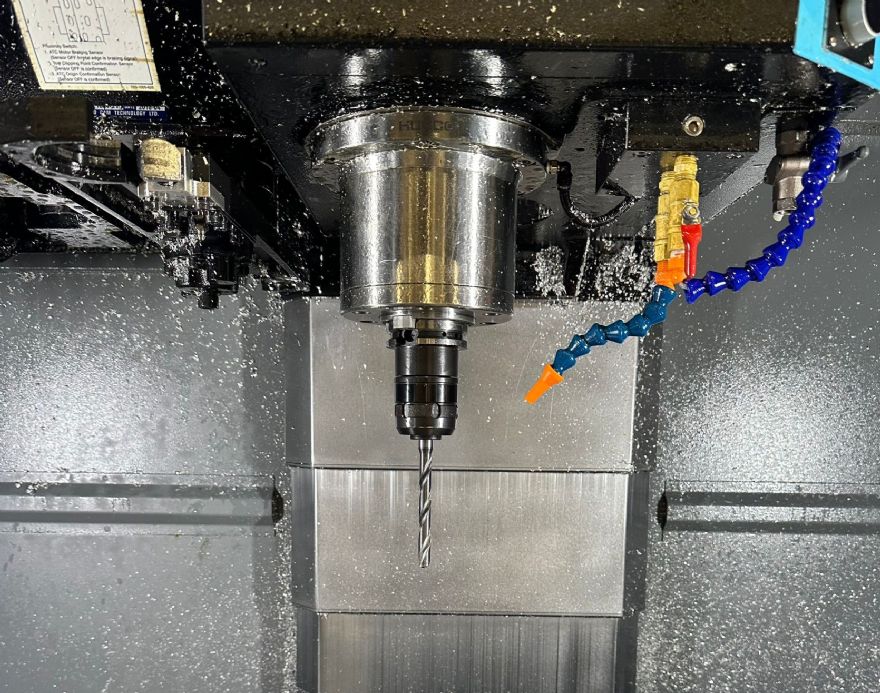

Onsite vending solutionHe continued: “We use a large variety of ITC tools from face mills, endmills, bullnose, ball nose endmills, drills and taps among other niche tooling. This variety of tooling is needed to support the many different items we machine, including but not limited to patterns, moulds, jigs, components, inserts, props and models. Add into this mix the fact that we machine a number of different materials and it is very clear that we need a tooling supplier with a huge variety of options. We also have an on-site vending solution from ITC with a comprehensive stock level that ITC keep fully serviced to support our business.”

Mr Johnston added: “When we conducted a full-cost analysis of our tooling and the total material removed, it is clearly evident that ITC’s tooling options are great value for money. We have managed to control costs over the years and the tooling manufacturer has helped to improve efficiencies while enabling our business to embrace the very latest tooling technology for composite machining.

“On more than one occasion, ITC has gone above and beyond to give full technical support in the implementation of new tooling, applications and machining strategies. When presented with a new material which we had very little knowledge of, ITC built a bespoke suite of tooling and trials to support our ambitions to effectively and efficiently machine the new material. The results have proven extremely encouraging and this certainly went a long way in building our confidence in working with that particular material.”

He concluded: “We naturally demand the highest quality and this applies to all aspects of the business. The CNC department can maintain and iteratively improve by leveraging ITC's knowledge and variety of tooling. Operating with a number of OEMs in a wide variety of sectors like automotive, aerospace, motorsport and marine, being adaptable to challenges is key. With the full support of ITC, we know we can attack any challenge and material with absolute confidence.”