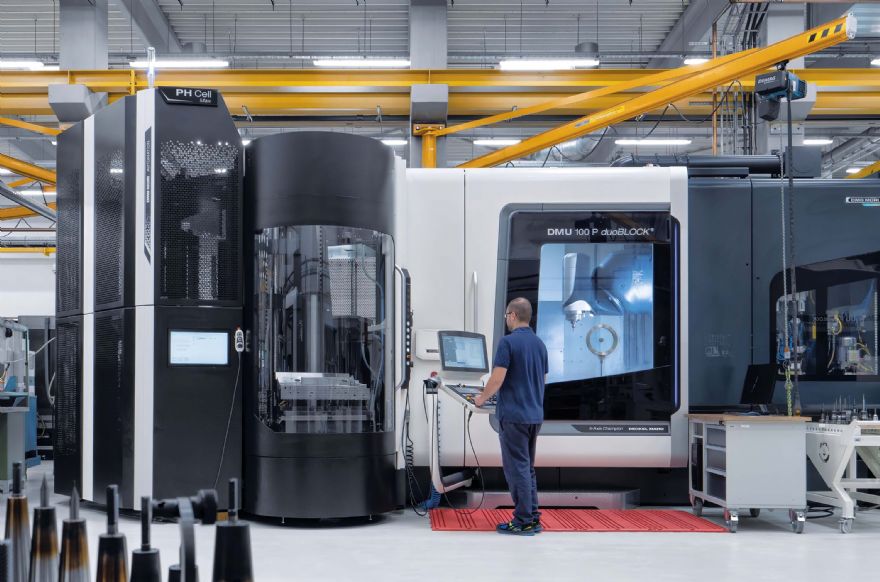

The DMU 100 P duoBLOCK 5-axis machining centre with PH Cell 2000 pallet storage and handling system on the shop floor at Euroform, Budapest

The DMU 100 P duoBLOCK 5-axis machining centre with PH Cell 2000 pallet storage and handling system on the shop floor at Euroform, BudapestBudapest-based

Euroform was established in 1993 to provide a tool and mould-making service from design to production and trialling. Approximately 70 staff fulfill innovative solutions for a range of different injection moulding processes, mainly for customers in the automotive industry.

The firm currently uses eight

DMG Mori machining centres for tool production, including DMU monoBLOCKs, an HSC 75 linear and, most recently, a DMU 100 P duoBLOCK with PH Cell 2000 automation system for pallet handling, to allow unattended production at night and during the weekends.

Euroform's managing partner Stefan Wolf said: "We play a pivotal role in automotive supply chains and our work begins in the early development phase of a new vehicle. Technical competence is crucial for exploiting the potential of innovative manufacturing solutions and CAD/CAM systems."

Euroform has been using machine tools from DMG Mori since 1995, latterly in a modern factory that it moved into in 2011 and expanded in 2016. Managing director Krisztina Zwick, responsible for day-to-day business at Euroform, said: “DMG Mori was one of the first machine tool manufacturers to open a subsidiary in Hungary, which meant that response times were always quick when service was required. Our latest investment in automation was necessary to utilise the machine during unattended shifts, giving us a competitive edge.”

Pictured left: a trial part being removed from an injection moulding machine at Euroform

Pictured left: a trial part being removed from an injection moulding machine at EuroformFive-axis simultaneous machining of workpieces up to 1,100 x 1,600mm and weighing 2,200kg had already been carried out on a DMU 100 P duoBLOCK in the factory. Euroform’s experience with the machining centre was consistently good, leading to the purchase in 2022 of a latest-generation model with a 1,000 x 1,250 x 1,000mm working envelope.

When Euroform ordered the new DMU 100 P duoBLOCK, DMG Mori already had a large pallet-handling system in development, based on the smaller, proven, modular PH Cell 300. The bigger capacity automation system handles pallets measuring up to 1,100mm in diameter, so is able to deploy Euroform's 1,000 x 800mm pallets. The PH Cell 2000 has 12 pallet positions on two levels and can accept workpieces up to 1,350mm tall (other variants are available with three or four racks housing up to 17 or 21 pallets respectively).

Pictured right: the injection moulded automotive part machined on an injection moulding machine

Pictured right: the injection moulded automotive part machined on an injection moulding machineAs Euroform almost exclusively manufactures one offs, pallet handling such as the PH Cell 2000 is the optimal solution. Operators set up jobs offline on several pallets using a zero-point clamping system while machining is in progress on another mould, so production downtime is minimal, even at night.

Another focus that accompanies business development at Euroform is digitalisation. The company has had a paperless working environment for many years, from design through to quality control. The mould maker is an enthusiastic adopter of the digital 'my DMG Mori' app when it comes to online service requests, which Ms Zwick said significantly accelerates the process of calling in a service technician.

Mr Wolf concluded: “Automated manufacturing and digital processes are essential, given the current challenges in the global marketplace. The recent Covid-19 pandemic, the war in Ukraine and high inflation have clearly shown us that we need to develop constantly in order to remain competitive. With targeted investment in technology and the training and further education of junior staff, we will continue to successfully meet these challenges.”