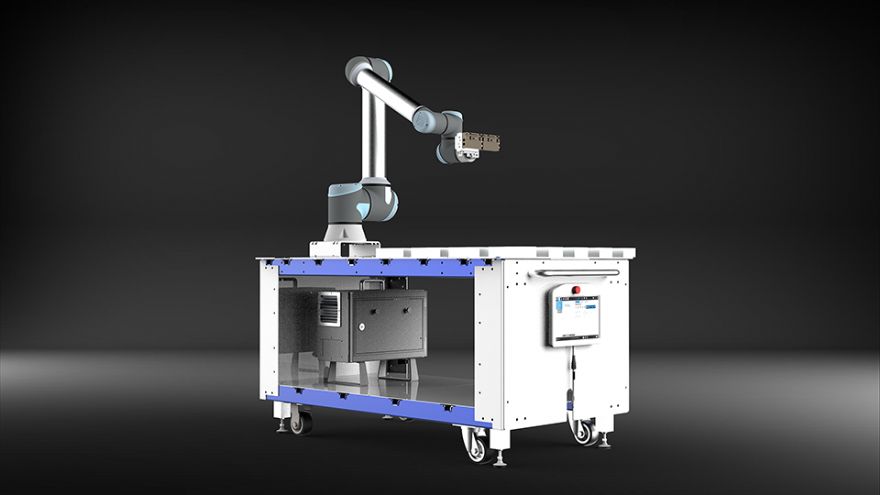

VersaBuilt Universal Robot machine-tending cart

VersaBuilt Universal Robot machine-tending cartBuckinghamshire-based

Thame Workholding, a leading supplier of standard and specialist work-holding equipment for over 40 years, will be showcasing a number of new innovations at

MACH 2024 (Hall 20, Stand 540), taking place 15-19 April at the NEC Birmingham.

Taking centre stage will be a VersaBuilt Universal Robot machine-tending cart, a simple plug and play machine-tending solution designed to automate material handling for CNC machines using Universal Robots collaborative robots (cobots). Users won’t need to buy lots of vices, know how to program robots, or purchase expensive ancillaries. The VersaBuilt mill solution allows flexibility and quick component changeovers.

The cart itself provides a mobile platform for the cobot and includes features to simplify machine tending applications, including: a universal grid top plate that allows for easy customisation of fixturing for different parts; integration with VersaBuilt's MultiGrip robotic gripping system for versatile part handling; and optional accessories such as VersaDoor for part alignment and a visual infeed system to aid the cobot in locating parts.

Visitors to

MACH 2024 are invited to the Thame Workholding to test the ease of programming of a Universal Robot and discover how easy it is to control them. The company will have a UR3 cobot for attendees to test drive and possibly win a prize!

High-precision chuckAlso highlighted at the show will be the new Samchully JB chuck, a high-precision, time-saving chuck manufactured by Samchully Machinery Co, Ltd, a South Korean company that designs and manufactures a variety of quality workholding products including power chucks, hydraulic cylinders, and scroll chucks.

The Samchully JB chuck (pictured left) is a hydraulic power chuck with a built-in jaw boring mechanism which eliminates the need for separate boring rings or pre-machined blanks and can significantly reduce the time it takes to set up the chuck for a new workpiece. Furthermore, the precise positioning of the boring mechanism allows for smaller passes when boring soft jaws which helps to minimise wear and tear on the jaws, extending their lifespan.

A built-in boring mechanism ensures that the jaws are perfectly centered with the chuck body which helps to improve machining accuracy and repeatability. The Samchully JB chuck is available in four sizes: 6, 8, 10, and 12in, and can be used for a wide range of machining applications.

Among the many other products on display will be the Thame Workholding (TEC) ‘Magic Chuck’ which is a cutting-edge medical application vacuum chuck for holding acetabular liners used in hip replacements.

Thame Workholding will also be exhibiting the HWR INOflex VL070 4-jaw compensation weight-reduced manual chuck for the clamping of round, square/rectangular and irregular shaped parts. It can be used with milling and turning centres for both internal and external clamping. Features include centric compensating clamping with four jaws; centric clamping with two jaws; clamping with fixed stop; weight reduction; and centrifugal force compensation.