Tri-Tech 3D

Tri-Tech 3D, a UK supplier of Stratasys 3-D printers based in Stoke-on-Trent, has supplied aerospace design and manufacturing business

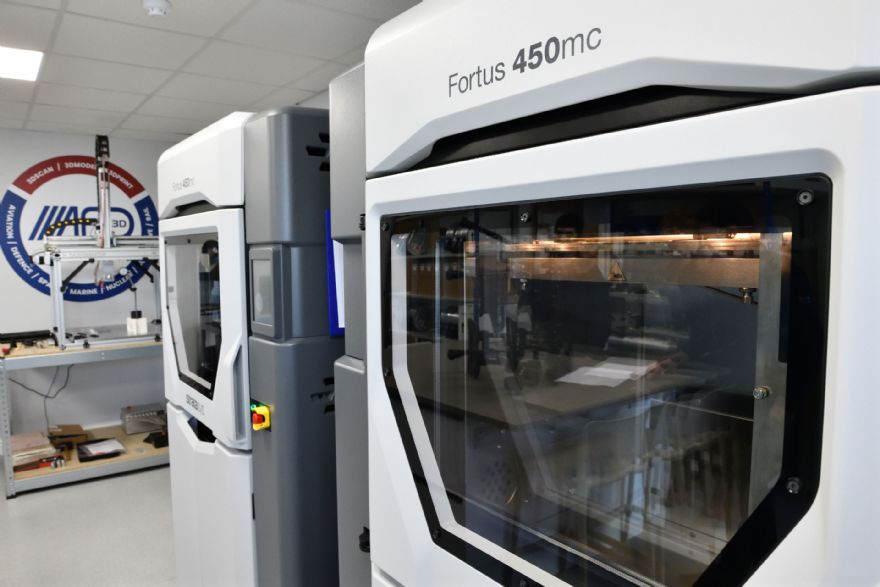

Airframe Designs in Blackpool with two Fortus 450mc systems. These fused deposition modelling (FDM) systems have enabled Airframe Designs to accurately and repeatably manufacture end-use parts and perform a world-leading National Aerospace Technology Exploitation Programme (NATEP) materials development project.

In July 2020, to support the NATEP materials project, Airframe Designs invested in its first Stratasys Fortus 450mc 3-D printer from Tri-Tech 3D, which installed the system and provided full training. The 18-month Government-funded project aims to be a world-first in airworthy part production using water-soluble supports, to speed up manufacturing and reduce potential for damage. This investment also enabled Airframe Designs to 3-D print customer parts using aerospace-certified materials, such as tooling and assembly aids, as well as more complex assemblies.

Originally, the Fortus 450mc was running 50% of the time on the NATEP project — and the other half producing customer parts. However, the machine reached its capacity for customer projects, and Airframe Designs was unable to take on more. So, in January this year, Airframe Designs purchased a second Fortus 450mc from Tri-Tech 3D, to double its manufacturing capacity.

Increased throughputAs well as taking on more work, the second system has enabled Airframe Designs to increase throughput. For example, when an urgent customer project came through for a complex 25-part assembly, the team was able to deliver it in four working days — something that wouldn’t have been possible with a single system.

Garry Sellick, additive manufacturing manager at Airframe Designs, said: “Now we have experience with the Fortus 450mc, we know with 95% confidence that it will build optimally. Typically we are achieving ±0.5mm accuracy, which is the tolerance we work to, and we are achieving a high level of repeatability. While we have had very few problems, we know Tri-Tech 3D is always on the end of the telephone if we need something.”

Robert Pitts, sales manager at Tri-Tech 3D, said “With the Fortus 450mc, the team at Airframe Designs has been able to edit print parameters to optimise machine performance, a benefit for the NATEP programme and for its customers. Available with a suite of validated materials, the Fortus 450mc is suitable for a wide range of aerospace applications, including cabin parts and tooling.”

The Fortus 450ms is an industrial Fused Deposition Modelling (FDM) 3-D printer that brings speed, cost and material advantages, as well as offers the repeatability and accuracy required in aerospace applications.