The impressive new bridge tools in actionBIG Kaiser

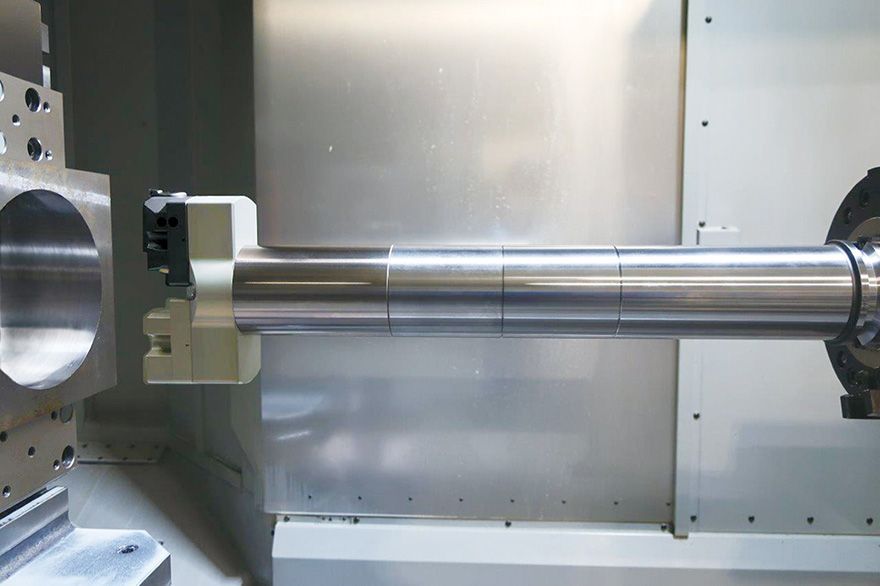

The impressive new bridge tools in actionBIG Kaiser, a leading manufacturer of precision holemaking systems, has now launched its new bridge tool that is complete with a smart damper holder. Available in the UK from Tamworth cutting tool manufacturer

Industrial Tooling Corporation (ITC), the new arrival marks the advent of a new family of bridge tools.

The new tool features the CK connection that is designed to excel in both rough and fine boring operations. Moreover, the bridge tools incorporate BIG Kaiser’s patented smart damper that has been engineered to reduce vibration when machining large-diameter bores up to 320mm.

Giampaolo Roccatello, chief sales and marketing officer for Europe at BIG Kaiser, said: “Now, we can seamlessly merge multiple cutting-edge technologies. This system brings together the exceptional modularity of the CK connection, the anti-chatter capabilities of our smart damper and our bridge tools. This facilitates roughing and fine-boring tasks up to 320mm. With the introduction of this new family of bridge tools, we are continuing to push the boundaries of innovation in solutions for large diameter deep-hole boring."

The integrated smart damper within these tools enhances connection stability, leading to improved precision during boring operations. This integration creates a remarkably stiff system when compared to using separate or modular components. Additionally, the newly introduced tools offer the convenience of supporting coolant supply through a central hole. This delivers cutting fluid directly to the cutting edge to prolong tool life and improve performance while simplifying the installation process.

Expected to serve a broad spectrum of industry sectors, the new bridge tools are set to be valuable assets in applications within the energy sector, defence, aerospace, and large manufacturing market sectors.