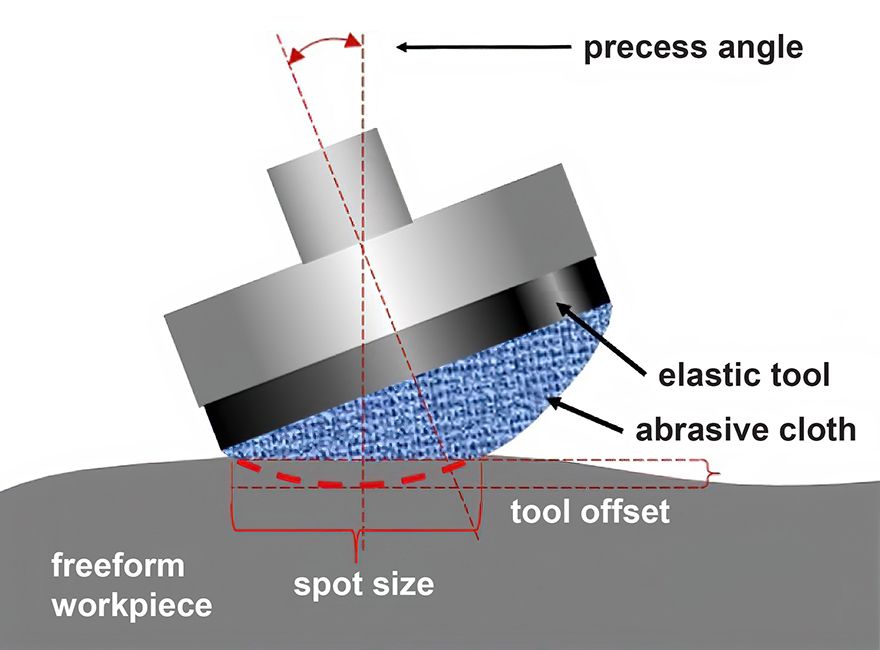

The principle of Shape Adaptive Grinding, the invention based on which Zeeko has won the 2024 King‘s Award for Enterprise in the Innovation category

The principle of Shape Adaptive Grinding, the invention based on which Zeeko has won the 2024 King‘s Award for Enterprise in the Innovation categoryEast Midlands-based

Zeeko, a poishing machine manufacturer, is one of only five companies this year to win two King’s Awards for Enterprise, one for international trade and the other for innovation. Founded in 2000, the company is an undisputed world leader in the development and production of computer-controlled (seven-axis CNC) optics polishing machines for complex, ultra-high-precision freeform applications.

Glass polishing for astronomy and space exploration was the main target for Zeeko in the early days, which was followed by higher volume production of optics for defence, semiconductor and X-ray applications, as well as for consumer products such as camera lenses. Optical artefacts from 3 to 1.5mm in diameter can be processed on Zeeko machines, whose intellectual property is protected by more than 50 worldwide patents. Each year the company spends a minimum of 20% of annual sales revenue on R&D.

The award for international trade is a result of a sharp upturn in these original specialist activities, plus additional sales in the last three years of both new machine platforms and tools for mainstream industrial use. The latter is referenced below in connection with Zeeko’s second King’s Award.

Exports account for about 98% of production, with key overseas markets being Japan, China, Taiwan and South Korea, followed by the USA, Canada, Mexico and continental Europe. Order intake is currently between £10 million and £12 million per year, compared with well below £2 million during the pandemic. Zeeko is not only generating its best sales ever, but current growth figures are higher than anticipated. The King's Award for Enterprise in the category of International Trade was based on this performance.

The 2024 award for innovation stems from the chance discovery of a new process that could easily have been overlooked, but which turned out to be extremely effective for the polishing and finishing of metal, ceramic and carbide items such as turbine blades, orthopaedic implants, precision moulds and ball valve components. Called Shape Adaptive Grinding (SAG), the technique utilises a low-cost, robotic machining platform together with associated tools and software. It can also be deployed on any CNC machine, such as a milling centre or multi-tasking lathe.

Pictured right: a selection of Zeeko SAG tools for use in its own robot polishing cells and other CNC machine tools

Pictured right: a selection of Zeeko SAG tools for use in its own robot polishing cells and other CNC machine toolsHoused in a separate factory in Coalville, Zeeko Industrial is a new division that has been established to build and market these robotic polishing cells worldwide. To realise the project, a manufacturing line for producing polishing tools has been built, a CAM (computer-aided manufacturing) software package developed and a remote calibration instrument invented.

Suitable for numerous finishing applications, the technology is especially well suited to polishing very hard materials, notably silicon and CVD-coated silicon carbide, as well as to finishing stainless steel and the relatively rough exterior of additively manufactured components.

The technology behind the innovation is a ductile material removal process that utilises a flexible, diamond-impregnated pad, a compliant, dwell time grinding action and the use of abrasive-free, regular coolant. In this way a polished surface is produced instead of a dull grey one.

Richard Freeman, managing director of Zeeko, commented: “We are delighted to receive two King's Awards this year. Our highly skilled and innovative team deserves this recognition. A high-technology manufacturing business rarely leads its competition by more than 18 months, so we are continually researching and innovating, both to grow and to protect our lead. This is evidenced by our exciting new dwell time hybrid grinding and polishing technology.

“We will always be grateful to the engineer in our research centre in Japan who, after observing an unexpectedly shiny finish appear after grinding the surface of a piece of silicon carbide, refused to dismiss it as a random event but instead investigated the phenomenon further. The SAG process is the result of that investigation.”