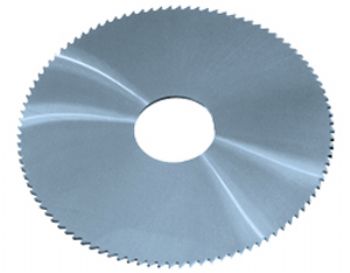

A new range of high-precision carbide circular saw blades for operations that include slotting, grooving, circlip grooving and general cutting operations has been introduced by the Baldock-based cutting-tool specialist Floyd Automatic Tooling Ltd (

www.floydautomatic.co.uk).

Manufactured to DIN1837 specifications, the 1101 slitting saws have been developed for the precision machining of low-depth slots with a feed per tooth ranging from 0.005 to 0.05mm.

Moreover, these cutters have a ‘tight tooth pitch’, an H7 internal diameter in the range 5-32mm, and external cutting diameters of 15, 20 , 25, 30 ,40, 50, 63, 80, 100, 125 and 160mm.

The blades are available with thicknesses from 0.1 to 0.5mm in 0.05mm increments, from 0.5 to 2mm in 0.1mm increments, and from 2 to 6mm in 0.5mm increments. The 15mm-diameter blades have the option of 24, 40, 48 or 64 teeth, while the 160mm-diameter blades have from 100 to 160 teeth.

For deep machining or long-slot production, Floyd has introduced its 1102 series of circular saw blades; these have internal and external dimensions identical to the 1101 series but a coarser tooth pitch. For intricate slotting operations, the company offers its 1103 series.

These extra-fine-pitch solid-carbide slitting saws are available in the diameter range 8-80mm. They are specifically for the machining of fragile workpieces and particularly recommended for applications on sliding-head lathes. Furthermore, the 1101, 1102 and 1103-series cutters can be supplied with a choice of coatings that include TiN, TiCN and TiAlN.

Floyd also offers saw blades for cutting slots and grooves that require a radius form. These blades range in diameter from 10 to 25mm in 5mm increments.