The tube-bending machine manufacturer Unison Ltd, Scarborough (

www.unisonltd.com), has launched what it believes is a new category of machine designed to substantially lower the cost and skill level required to produce precision tubular parts in small volumes.

Target sectors for the new machine, which can bend tube diameters up to 50mm, include shipbuilding and oil and gas.

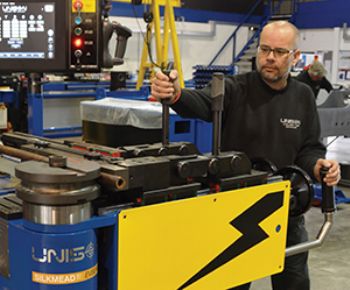

The EvBend 2000 rotary-draw tube-bending machine combines manual set-up with semi-manual operation of the bending arm, which features servomotor power assistance to make the machine easy to program and use (just a few minutes of training are required). That said, very precise results are assured by the CNC system, which controls the tube feed, carriage rotation and bend axes.

The EvBend 2000 is a variant of Unison’s EvBend 1000 manual machine, which accommodates tube diameters up to 22mm and is widely used in the aerospace sector. The 2000-series machines offer bend torques up to 5,500Nm to assist operation of the bend arm.

Operator safety is assured by the requirement for human force on the bend arm to engage the power assistance, plus a ‘dead man’s switch’ that provides a fail-safe mechanism (this instantly removes the power assistance if the operator lets go or relaxes their grip on the handle). Moreover, making prototypes or small quantities — or reverse engineering components — is very easy using this process, as the bending program can be broken down into simple steps.

Users can create bending programs in two ways. The first is by entering the standard tube bending information (XYZ/YBC/LRA values, or the distance tube is fed out, rotated, and the angle of bend) into dialogue screens on the EvBend’s Windows-type operator interface (this data can also be transferred from a co-ordinate measuring

machine).

Alternatively, users can program the machine using a teaching mode that is particularly easy to use; a part can be reverse-engineered by bending and comparing a tube against an existing part, with the user capturing the underlying material feed, rotation, and angle of bend information as the desired points are reached.

Once the required bend data is entered, the user can start bending parts, under the interactive guidance of the machine. The precision and repeatability of the feed, rotation and bending operations are assured by an electromagnetic braking system, with encoder feedback on each axis ensuring that all movements are accurate.

EvBend machines can be configured with a right-hand or left-hand bending head; change-over takes about 15min.