To produce new spray heads for forging presses, SMS group (

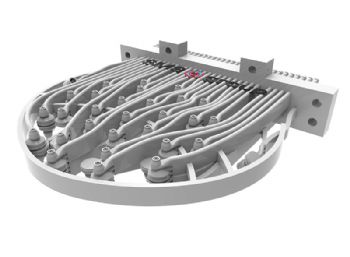

www.sms-group.com) is taking advantage of the benefits offered by additive manufacturing (AM); the process allows extremely lightweight and compact spray heads to be manufactured — heads that are tailored to the requirements of individual dies.

Flexible actuation of individual nozzles, paired with fast material handling and a homogeneously distributed mist, shortens press cycle times and extends the service life of dies.

Spray heads fitted in closed-die forging presses serve to remove scale from the dies between individual press strokes, cool the surface, apply lubricants and dry the die.

The starting material is fine powder based on polyamide, and the result is 3-D printed spray heads that are 90% lighter than conventional heads made from steel, allowing the use of faster handling systems.

3-D printing gives SMS engineers the opportunity to deviate from the laminar design of previous-generation spray heads.

The perforated structure prevents spray medium from accumulating on the spray head, while the interior of the individual channels is flow-optimised and precludes the formation of deposits.

As a further benefit, 3-D printed spray heads have no parting lines, which means the spray medium is not exposed to air during downtime and cannot dry out.