The Derbyshire-based co-ordinate measuring machine (CMM) manufacturer LK Metrology Ltd (

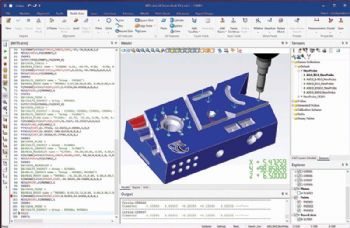

www.LKmetrology.com) has introduced a new version of its Camio software (8.5).

Designed to increase productivity in the inspection department, improve the quality of data collected, reduce measuring cycle times and ‘accelerate time to market for new products’, the software is used not only on the company’s own CMMs but also on other manufacturers’ platforms, to which it can be retrofitted.

Camio drives accurate and efficient programs for measuring geometric features, as well as analysing surfaces and generating part-to-CAD comparisons.

Moreover, the software’s interoperability across CMM platforms, sensor technology and manufacturing sites offers a significant advantage; and the latest version includes a number of programming updates.

For example: reference point system alignments have been re-organised; ‘toggling’ between probe angles has been simplified; more-precise and pronounced warning messages are provided for users when setting up the machine with program parameters outside minimum or maximum limits; the ‘GOTO’ command now allows the user to specify the number of axes for movement; and the ACIS CAD engine and support for third-party CAD formats have been updated.

Meanwhile, interface upgrades include: improvements to window docking to allow users to customise the interface for a specific task or application more easily; the display of CAD layers in a separate window to provide better access; CAD orientation buttons that allow users to keep the current zoom level; and mouse/pointer co-ordinates in the status bar for the quick estimation of dimensions.

Furthermore, laser and point cloud improvements include a new offset parameter for point detection, plus the export of point clouds in ‘Geomagic GDP’ format to interface with 3D Systems’ processing software (this capability allows accurate models to be created from scan data or for quality control measurements).

To ensure that CAMIO 8.5 is even easier to use, setting up the Machine Launch Utility for offline programming has been simplified.

Moreover, there are additional options for opening and/or printing Camio reports, and it is possible to relocate a single ‘rack stall’ instead of all the stalls.

Renishaw’s PHS1 servo positioning head is now supported, as is the ACR2 modular extension arm auto-change rack, which allows any number of racks to be positioned anywhere within the machine volume. Renishaw’s SP80 head and auto-change rack are also supported.