Continental has opened a company-wide competence centre for 3-D printing in Germany at its electronics plant in Karben; it is run by Continental Engineering Services which, in addition to additive manufacturing, develops technologies used in high-performance CNC machining, injection moulding and laser welding, as well as ‘state of the art’ electronics manufacturing for printed circuit board assembly.

Karben plant manager Torsten Rauch said: “3-D printing is becoming increasingly important thanks to its many advantages, as confirmed by the ever-increasing demand for additively manufactured parts.

“With our competence centre in Karben we are now able to test technologies, develop processes and procedures and apply them in our production facilities world-wide.”

Stefan Kammann, head of additive design and manufacturing within the product solutions division at Continental Engineering Services, said: “We make 3-D scans of components, edit them then print them in the most appropriate material.

“For example, we can produce high-quality metal parts in place of plastic parts; the process also lowers production costs with shorter production times.”

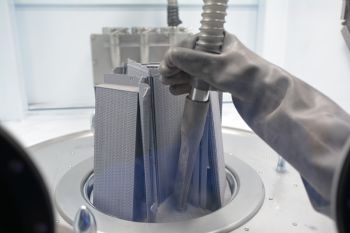

In the new competence centre, Continental has a variety of 3-D printing technologies at its disposal.

For example, the selective laser melting (SLM) machine plays an important role in the production of metal parts (the process involves selective melting of metal powder to produce a three-dimensional structure layer by layer), while technologies that involve the use of plastics include: selective laser sintering (SLS), which uses various plastics such as PA, PP and polystyrene; stereolithography (SLA); digital light printing (DLP); and fused deposition modelling (FDM).