Lancashire-based Fintek has gained GE certification for mass surface finishing at its facility in Bury. Adding to its existing AS9100 and AS9001, the new certification is an important milestone for the company as it continues to expand its sub-contract surface-finishing services in the aerospace sector.

Fintek (

www.fintek.co.uk) is engaged in pioneering work with several aerospace component manufacturers, working closely with them to eliminate production bottlenecks that result from hand finishing and traditional finishing methods not being able to achieve the high-quality surface finishing required in ever-shorter lead times.

Of particular concern for many manufacturers of aerospace parts is unseen damage caused by manual deburring using small powered hand tools; accidental nicks can compromise fatigue requirements, possibly with catastrophic consequences.

Another hand finishing issue is missed burrs that are subsequently peened over, as these can also become sources of component failure.

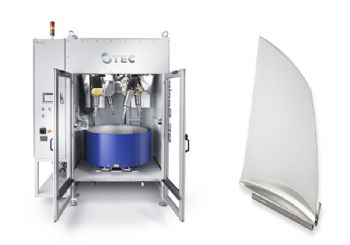

Key in addressing these issues is the use of highly controllable ‘stream finishing’ systems from OTEC Präzisionsfinish GmbH, which Fintek represents in the UK. Components benefitting from this type of surface finishing include turbine blades, extremely thin parts, gear wheels, fasteners and cutting tools.

To accommodate additional stream finishing units and meet demand for these processes, Fintek is also planning to extend its facility.

Managing director Jonathan Dean said: “These are exciting times, as much of the R&D work we have undertaken with Formula One teams is proving to be adaptable to aerospace and we can offer manufacturers mass finishing options to boost productivity and quality where previously they did not exist. This GE certification is another step forward for us.”