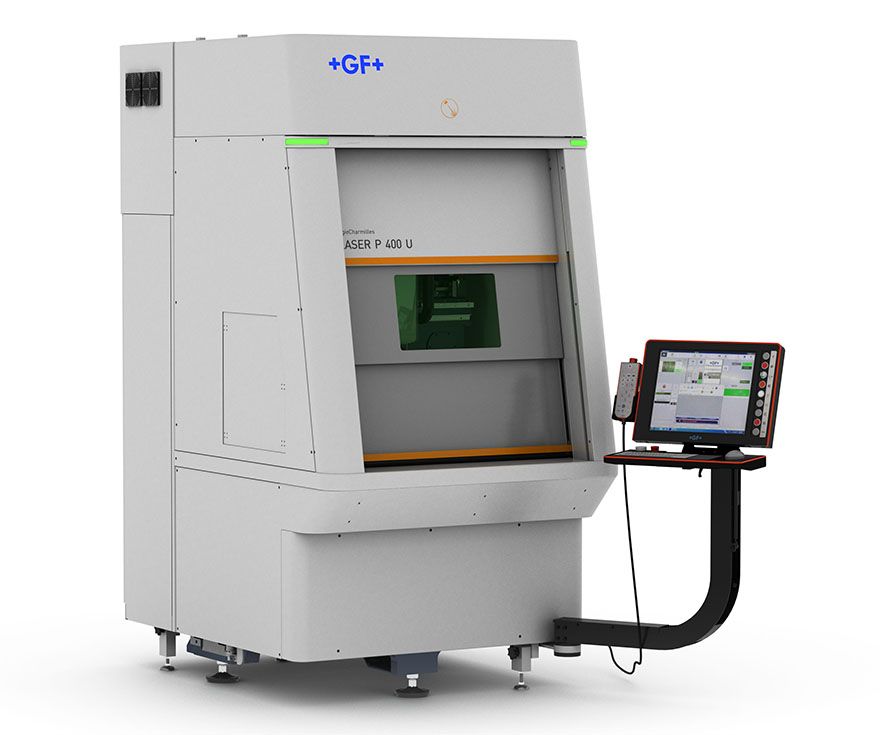

The five-axis AgieCharmilles Laser P 400U provides customers with high-quality laser texturing, blasting, engraving and marking

The five-axis AgieCharmilles Laser P 400U provides customers with high-quality laser texturing, blasting, engraving and markingDemand is high, as are cost-down pressures, and the trend towards miniaturisation is having a marked effect on traditional production supply chains — especially on the manufacture of mould tools required in the production of electronic micro-components. As a consequence, there is a drive within the sector to invest in manufacturing solutions that help simplify increasingly complex processes, reduce spiralling costs and help offset ongoing skills shortages. This has led to a focus on innovative and disruptive technologies and one of these, quite literally creating waves, is laser ablation.

The growing complexity of electronic components is pushing some traditional technologies, like die-sinking EDM and milling, to their limits. While EDM and milling clearly have their advantages, it is with the most complex applications, where new approaches and ’thinking outside the box’ technologies could have a role to play.

Martin Spencer,

GF Machining Solutions Ltd’s managing director, said: “Increasingly, laser technology is being used to either replace, or work in combination with, traditional machining technologies to manufacture micro-cavities used in the production of connectors. An example of this is in the manufacture of pin cores for optical lenses in cameras.”

In mould making, the traditional EDM and milling multiple-step processes, require the production of many high-precision electrodes and can involve long set-up and machining times, as well as a reliance on skilled staff.

Furthermore, complex mould tools and mould inserts often require the use of multiple technologies and the design and management of multiple manufacturing ‘steps’ such as the use and integration of different cutting tools, electrodes and work handling. With each of these individual steps — mistakes can occur. Another issue is the increasing use of non-conductive materials such as ceramics or silicon carbide, to manufacture electronic components which, owing to the materials’ properties and component accuracies and surface finish requirements, are difficult to machine using traditional technologies.

The rise of laser technologyLaser technology enables complex, high-quality mould tools for connectors and micro-cavities and micro-components to be manufactured and currently two laser technologies, nanosecond and femtosecond are available.

Nanosecond pulse technology has been around for a while and still has many uses, but it is femtosecond pulse technology with its ability to deliver the highest precision, with burr-free ablation, that looks set to dominate the electronics sector into the future. The appeal of this technology is that no electrodes are required, non-conductive materials can be machined, uniformity/consistency over large areas can be achieved, and functional textures can be reproduced.

Laser technology also has a number of advantages over milling, including: no consumables are required; it is a contactless technology, so hard and brittle materials can be machined; produces burr-free results; and small, intricate features and details can be machined. Laser technology provides a clean, repeatable process that does not require electrodes and does not use die-sinking EDM oil in the machining process.

A combined laser and EDM technology solution is available from GF Machining Solutions that is ideal for electronic connector moulds. The innovative AgieCharmilles five-axis LASER P 400U provides customers with high-quality laser texturing, blasting, engraving and marking. Used in combination with EDM for finishing, an automotive customer was able to revamp its production processes and significantly reduce mould tool lead times from roughing through to pre-finishing.

The customer’s previously used process to machine electrodes for its die-sink operations, took 15hr to complete. The new process, using laser ablation took only 12min to rough and pre-finish the moulds followed by 4.5hr of EDM finishing.

Furthermore, end users that invest in flexible femtosecond laser equipment for one application — for example, to produce electronic connectors — can also use the same equipment for many other applications. The technology can be used to machine a variety of materials, including copper, gold, silver, nickel, hardened metals, glass, sapphire, ruby and polymers — all with repeatable precision.

Martin Spencer concluded: “Our LASER P 400U, using our Lasercam software, can help customers reduce their die-sinking processes or eliminate its use, completely. The machine can engrave and produce shapes and forms irrespective of a material’s hardness or conductivity, in just one set up.”