The Index G200 turn-mill centre being operated by lead engineer Nick Morton on the shopfloor at the Stockport factory of HDL

The Index G200 turn-mill centre being operated by lead engineer Nick Morton on the shopfloor at the Stockport factory of HDLMedical systems manufactured by

Hollingworth Design Ltd (HDL) at its Stockport factory now contain components milled and turned in-house, avoiding the unreliability and cost of sourcing them from sub-contractors. Only sheet metalwork continues to be produced by third parties. The first CNC lathe and mill were installed in 2017, followed by another turning centre and then a German-built Index G200 twin-spindle, triple-turret, turn-mill centre supplied in 2020 by

Kingsbury, the sole agent for index in the UK.

Since then, the number of lathes and mills on-site has doubled to eight, including a smaller capacity Index C100 and HDL’s first automated prismatic machining cell, a robot-fed, five-axis, HSK-A63 spindle C12 from Hermle, Germany, also represented exclusively in the UK by Kingsbury.

The same period has also seen the arrival of a CNC mitring saw, an Aberlink coordinate measuring machine, a Keyence optical inspection system and the company’s first quality control inspector, Simon Tweedie. Other new members of staff are Richard Binks, who is dedicated to sub-contract sales, and Nick Mort, lead engineer in charge of the CNC section. Mr Mort said: “The sub-contract side of our business has increased five-fold to 25% of turnover in the last two years and we are aiming to increase it to 50% by 2026.”

The 65mm bar capacity Index G200, which is fitted with a 3m bar magazine, is playing a major role in fulfilling the growing number of contracts. The upper, double-tool carrier has a 360deg B-axis and a ±65mm Y-axis. On one side there is a 14-station, live tool turret rated at 16kW/16Nm (25% DC) and 7,200rev/min maximum speed. On the other side there is an HSK-A40 22kW/52Nm (25% DC) milling spindle with automatic cutter exchange, enabling considerable machining versatility in combination with the two lower turrets that also serve the 6,000rev/min 32kW main and counter spindles.

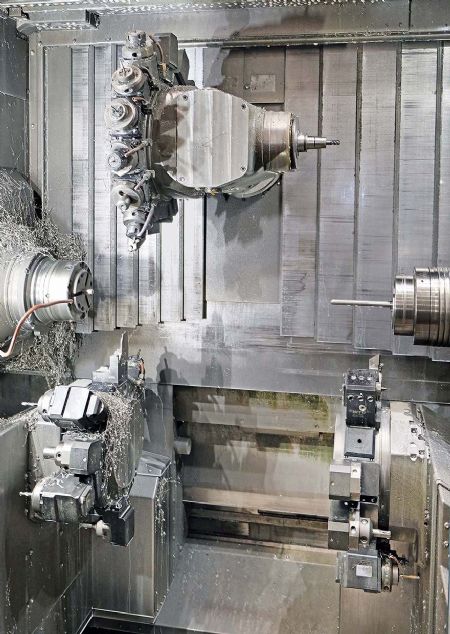

Pictured right: machining area of the G200, showing the 360deg upper tool carrier comprising a 14-station turret and an HSK-A40 tool spindle

Pictured right: machining area of the G200, showing the 360deg upper tool carrier comprising a 14-station turret and an HSK-A40 tool spindleArranged in mirror image, each lower turret has an independent ± 45mm Y-axis and an identical rating to the turret at the top. To optimise productivity, it is possible to use all three turrets simultaneously at either the main or counter spindle, without interference.

Alternatively, simultaneous machining the front end of a component at the main spindle and the reverse end at the counter spindle, in contrast to sequential machining on HDL’s earlier lathes, has cut cycle times dramatically. To produce a typical turned, threaded and engraved brass manifold component, for example, the typical cycle time has been reduced from 4 to 1.5min and similar efficiency is gained when producing sub-contract parts for other OEMs.

Given the lathe’s high power and versatility, it is not surprising that there was a tendency to prioritise the use of this Index turn-mill centre when considering which machine to employ for producing a new or existing part, even if it mostly entailed prismatic machining using the driven tools. So another lathe from the same source, an Index C100 having 42mm bar capacity and a more conventional three-turret configuration, was bought to produce most of the turn-milled components for internal use, freeing the larger lathe to fulfil mainly sub-contract work, which is often more complex and generally larger. Mr Mort added: “We had no hesitation returning to Kingsbury for another Index lathe, as the first proved very reliable and the backup from the agent was prompt, efficient and friendly.”

For that reason, in early 2023 when HDL wanted to acquire its first automated machining centre, it selected Kingsbury again for the purchase of the Hermle cell. It was preceded by a stand-alone, five-axis, 30-taper mill-turn machine from another supplier that was being used almost exclusively for producing aluminium parts for a bicycle manufacturer in the north of England. The contract was growing in variety and volume, especially with the introduction of an electric bike, so automation was the obvious choice for producing the parts more cost effectively.

Pictured left: brass components machined from bar in the Index G200

Pictured left: brass components machined from bar in the Index G200As the bicycle components are relatively light, it was decided that a Hermle RS05 robot for handling individual billets into the machining area and returning finished parts was preferable to automated pallet exchange. The latter would have incurred more cost to buy the pallets and work-holding equipment and entailed extra work for fixturing parts and removing them.

Now production of the bicycle parts is shared between the 30-taper machine and the Hermle. Prototypes are produced on the former, while larger batches are put onto the latter; 50-off, say, if piece part cycle time is 15 to 20min, or 200-off minimum in the case of shorter cycles.

To support HDL while its engineers were familiarising themselves with operating the Hermle cell and programming it with the help of a new seat of SolidWorks CAD/CAM, Kingsbury provided a suite of eight turnkey packages, each comprising a program, set-up sheet and list of recommended tooling.

Mr Mort concluded: “These days, it is difficult to find skilled setter-operators. An automated cell like the Hermle helps to mitigate the situation, as once it is set it just runs, including overnight, producing parts to tolerances from ±0.25mm right down to ±10µm.”

In addition to the medical and bicycle manufacturing sectors, today HDL regularly serves motorsport, aerospace and the marine industry. It also supplies tight-tolerance, mainly titanium parts that go into test equipment built by Hyderogen, a hydrogen technology consultancy owned by Kris Hyde, who is joint managing director of HDL together with the company founder, Paul Hollingworth.