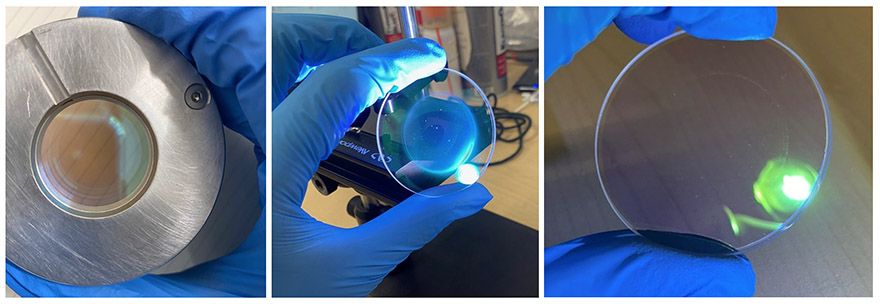

The image on the left shows clean glass within its chamber holder assembly — before any welding has occurred; the centre image shows the kind of deposits that typically occur with Laser in Vacuum welding systems that do not include optical protection; and the image on the right shows a window after 2hr of welding using CVE’s unique optics protection systemCambridge Vacuum Engineering

The image on the left shows clean glass within its chamber holder assembly — before any welding has occurred; the centre image shows the kind of deposits that typically occur with Laser in Vacuum welding systems that do not include optical protection; and the image on the right shows a window after 2hr of welding using CVE’s unique optics protection systemCambridge Vacuum Engineering (CVE), a power beam welding specialist, has completed a Knowledge Transfer Partnership (KTP) with

Cranfield University that will increase welding options available to engineers worldwide. Together, the two organisations have solved the undesirable optics contamination phenomenon associated with Laser in Vacuum welding, paving the way for full-scale industrial exploitation of the technology.

The conclusion of the KTP is set to yield tangible benefits for companies that want to achieve deeper penetration welds, while also improving weld quality, reducing oxidation, and minimising the time needed for post-welding part cleaning,

Laser in Vacuum welding is a relatively new joining technique that can be used to tackle some of the most demanding welding tasks. The technique can achieve two- to three-times the depth of weld compared to conventional laser welding methods. However, to date, the issue of optics contamination has hindered its widespread adoption across industry.

With a shared vision to drive forward innovation, CVE and Cranfield University joined forces to research innovative solutions to this persistent issue and enable the seamless integration of Laser in Vacuum welding into various industrial applications. Over the last two years, using

Innovate UK funding, the teams set up test systems at both CVE and Cranfield to study different aspects of the Laser in Vacuum process and trial various concepts and solutions.

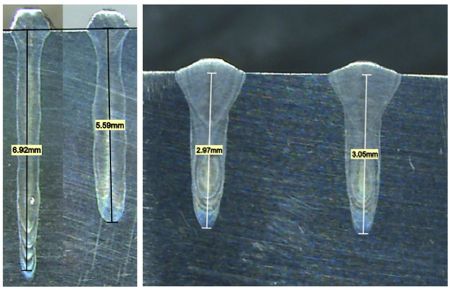

Pictured right: the left image shows how weld quality and depth degrades over time with traditional Laser in Vacuum solutions where chamber deposits and optical contamination occur; the image on the far right shows that there is no difference in weld quality when using CVE’s optical protection system. The weld on the left was made when the chamber glass was brand new; while the weld on the right was made when the optical glass had been in use for 3hr

Pictured right: the left image shows how weld quality and depth degrades over time with traditional Laser in Vacuum solutions where chamber deposits and optical contamination occur; the image on the far right shows that there is no difference in weld quality when using CVE’s optical protection system. The weld on the left was made when the chamber glass was brand new; while the weld on the right was made when the optical glass had been in use for 3hrExperiments on these systems provided the team with a robust data set on various phenomena associated with optical contamination, as well as the secondary effects of the potential identified solutions. This data was then used to develop a unique optics protection system — using a first principles, physics-based approach — that operates effectively with very low levels of particulate generation. Several trials were conducted with customers, providing further assurances about the capabilities of Laser in Vacuum welding, and validating weld quality in a range of applications, materials and joint configurations.

The project has subsequently been awarded the highest grade of ‘Outstanding’ by

Innovate UK and Cambridge Vacuum Engineering is now building Laser in Vacuum welding machines featuring the technology for its customers in industry.

Max Nentwich, KTP project lead and head laser development engineer at CVE, said: “This project is a significant milestone in the commercialisation of Laser in Vacuum welding. By addressing the optics contamination issue, we can now unlock the full potential of this form of welding — enabling it to reach full industrial maturity. As a team, we are incredibly proud of this breakthrough and grateful to Innovate UK and Cranfield for their support. On a personal level, as a recent graduate, I am delighted to have led such a meaningful project. It was a privilege to conduct research that will have immediate implications for industry and help deliver enhanced levels of productivity, efficiency, and quality for end users.”

CVE’s optical protection system ensures cleanliness levels of welded parts comparable with electron beam welding, while guaranteeing a long laser coupling-in window life. The low-cost consumable windows last for up to three hours of welding at a low power (3kW) with no appreciable weld degradation.

CVE sales director Steve Horrex said: “Congratulations to Max and the team at Cranfield for completing this project with such exceptional results. It is rare for a recent graduate to be put in charge of such a large KTP, but we knew from the start that Max was the right project lead. To be awarded such an impressive grade by Innovate UK validates the future impact of this project and we look forward to taking the results to market to deliver commercial benefits across the sectors we work in.”

Pictured left: the left image shows what a contaminated chamber can look like after welding titanium; the right image shows a clean chamber after welding using CVE’s unique optics protection system which operates with very low levels of particulate generation

Pictured left: the left image shows what a contaminated chamber can look like after welding titanium; the right image shows a clean chamber after welding using CVE’s unique optics protection system which operates with very low levels of particulate generationDr Wojciech Suder, senior lecturer at Cranfield University, said: “Laser Welding in Vacuum can overcome many limitations of atmospheric laser welding, opening a myriad of new applications. Working with Max and the CVE team enabled us to put the required expertise together quickly and develop this technology very efficiently, making real impact. Well done to the team for converting a lab idea into a commercial system in just over two years. I look forward to seeing this technology revolutionising thick section and specialised welding applications.”

The process complements electron beam and standard laser welding techniques, with each approach possessing different strengths and weaknesses. Offering all three types of welding, Cambridge Vacuum Engineering can take a technology agnostic approach, providing customers with bespoke solutions optimised to meet different application needs and engineering challenges.

Laser in Vacuum welding is most suited to projects where higher penetration welds are required or gas-sensitive materials are used. In these scenarios, standard laser welding can struggle to achieve the right results. Many of the process variables influencing weld quality associated with standard laser welding, such as shielding gas composition, nozzle design, and melt pool instabilities, are eliminated using a vacuum.