The German machine tool manufacturer

EMAG Koepfer GmbH says the ‘supposed fact’ that electric cars do not have any transmissions is wrong but persists in the public eye, the assumption being that the electric motor does not require any gear ratio given its stable torque. “In practice, however, there are numerous gearing elements on components such as the drive shaft, rotor shaft, or axle drive, and their component quality must be exceptional so that, for example, there are no loud running noises, as these would be audible given the quietness of the electric motor.”

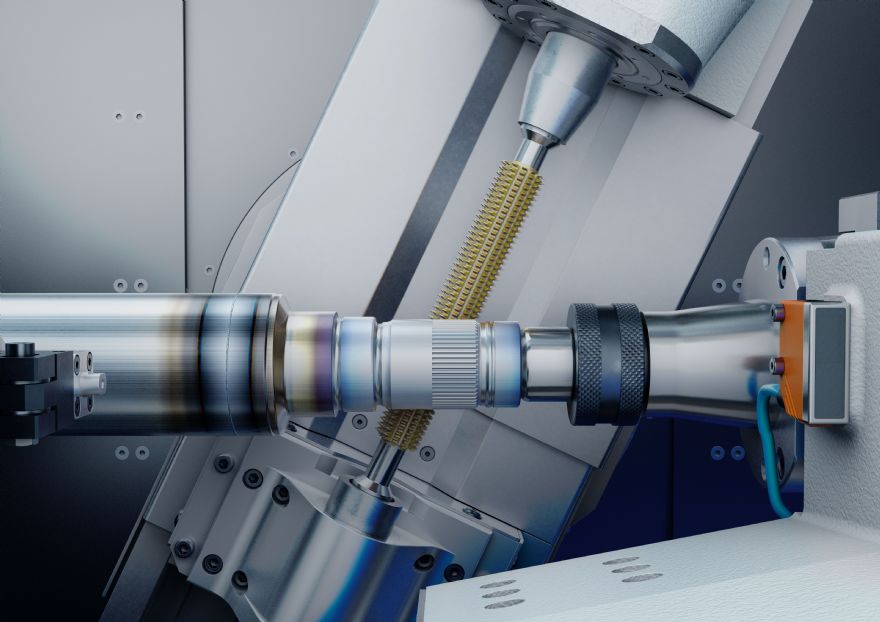

For cost-effective rotor-shaft machining, EMAG’s HLC 150 H gear-hobbing machine offers a high level of productivity for components with a maximum length of 500mm and a weight of 10kg. The design of the milling head and its large swivel angle in two interpolated axes ensures that gear hobbing is very smooth, and the resulting gear quality is high. Moreover, rotor shafts can be produced in a cycle time of only 35sec at a gear quality of DIN Q7, while the horizontal positioning of the workpiece prevents ‘chip clusters’ from forming.

“Furthermore, machine builders planning complete lines for the rotor shafts in which all machining processes are linked one after the other — from the soft machining of the blanks to the final hard machining, including the tooth flank grinding processes or skiving hobbing — will find that the HLC 150 H can be readily integrated, thanks to its high-speed gantry loader. This picks up the components from EMAG’s own TrackMotion system, which can ‘drive through’ the machines on the line.

“EMAG Koepfer’s K 160 gear-hobbing machine, a solution for components with a maximum length of 300mm and weight of 2.5kg, can be applied to assembled rotor shafts — and this machine can be integrated into EMAG lines or largely automated.”

EMAG Koepfer says that overall, the company sees itself as well equipped for the growing e-car boom, particularly regarding setting up high-volume production, as its solutions can be integrated into the manufacturing flow in a variety of ways.