At

TU Wien — located in Vienna, and Austria’s largest research and educational institution in the field of technology and natural sciences — an important step has now been taken towards creating replacement tissue in the laboratory, using a technique that differs significantly from other methods used around the world.

It uses a special high-resolution 3-D printing process to create tiny, porous spheres made of biocompatible and degradable plastic, which are then colonised with cells. Moreover, these spheroids can be arranged in any geometry, with the cells of the different units combining seamlessly to form a uniform, living tissue. Cartilage tissue, with which the concept has now been demonstrated at TU Wien, was ‘previously considered particularly challenging in this respect’.

Oliver Kopinski-Grünwald, from the Institute of Materials Science and Technology at TU Wien, and one of the authors of the current study, said: “Cultivating cartilage cells from stem cells is not the biggest challenge. The main problem is that you usually have little control over the shape of the resulting tissue. This is also due to the fact that such stem cell clumps change their shape over time and often shrink.

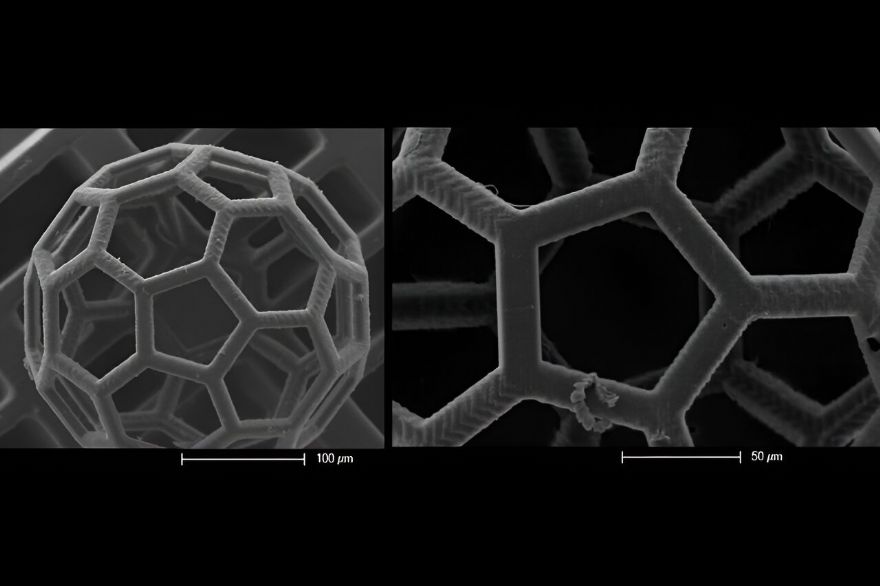

Tiny cage-like structuresHe continued: “To prevent this, we are working with specially developed laser-based high-resolution 3-D printing systems that create tiny cage-like structures that look like mini footballs and have a diameter of just 0.3mm. They serve as a support structure and form compact building blocks that can then be assembled into any shape.”

Professor Aleksandr Ovsianikov, who is head of the ‘3-D Printing and Biofabrication’ research group at TU Wien, added: “Stem cells are first introduced into these football-shaped mini-cages, which quickly fill the tiny volume completely. In this way, we can reliably produce tissue elements in which the cells are evenly distributed while giving a very high-cell density. This would not have been possible with previous approaches.”

The team used differentiated stem cells, those that can no longer develop into any type of tissue but are already predetermined to form a specific type of tissue, in this case cartilage tissue.

Mr Kopinski-Grünwald concluded: “Our initial goal will be to produce small, tailor-made pieces of cartilage tissue that can be inserted into existing cartilage material after an injury. We have already been able to show that our method for producing cartilage tissue using spherical micro-scaffolds works in principle and has decisive advantages over other technologies.”