Northern Ireland-based

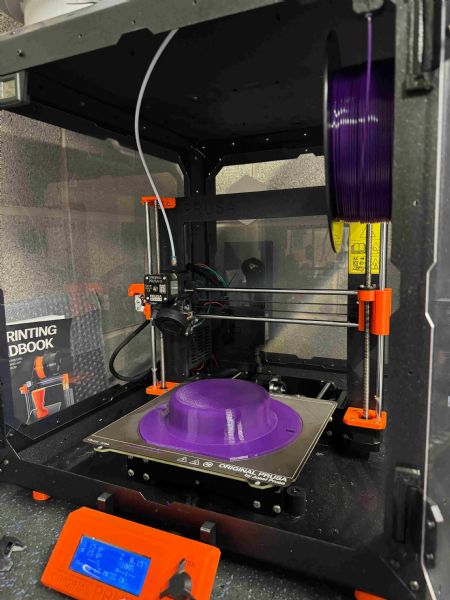

Technidrive, an industrial drives specialist, has invested in a ‘state of the art’ 3-D printer to produce high-quality products with faster development times. Operational since 2023, Technidrive can now ensure a seamless supply of technical parts, regardless of supply chain disruption. The Portadown company’s new 3-D printer has the capacity to produce a variety of technical parts and is used for fast prototyping in product development and producing custom or low-volume parts that can be difficult or expensive to manufacture using traditional methods.

The application of the 3-D printer will extend beyond addressing immediate supply chain challenges. Technidrive also uses the technology for a range of innovative projects — allowing for quick validation of ideas before getting a machinist to make the product out of steel. This means that design prototypes can be produced quickly without having to go into full-scale production. As a result, Technidrive can develop higher-quality bespoke parts more quickly. Producing design prototypes with 3-D printing enables Technidrive to offer customers cost-effective, tailored solutions, enhancing the product development process.

For example, this allows the company to produce safety covers for gearboxes on demand. In cases where standard safety covers don’t fit a gearbox, Technidrive can design its own and supply to customers. Safety covers are crucial for protecting equipment and ensuring workplace safety, and 3-D printing the parts ensures precise fitting, addresses specific needs promptly, therefore contributing to industry safety standards. The company can also design workshop tools and fixtures, streamlining daily operations.

Jonathan Johnston, project engineer at Technidrive, said: “Following the global supply chain disruptions caused by the Covid-19 pandemic, we faced difficulties in sourcing critical parts. Because of this, we decided to purchase a brand new 3-D printer that lets us test and perfect technical components such as our safety covers for gearboxes and workshop tools.

“Investing in the latest 3-D printing technology has been a game-changer in fulfilling customer requests. We have the ability to swiftly prototype and deliver high-quality, custom components that meet market demands across all sectors, reinforcing our commitment to exceeding customer expectations. This technology further enhances Technidrive’s bespoke approach to project customisation, providing precise system design and integration for challenging applications. It reinforces our position as an innovative solutions provider.”

In addition, the 3-D printer reduces material waste linked with traditional machining processes. The ability to prototype and validate designs before committing to large-scale production contributes to a more sustainable approach to manufacturing, aligning with the company’s sustainability approach.

While the initial focus is on product development and prototyping, Technidrive envisions many future applications of the 3-D printer, including exploring opportunities for multi-material printing.