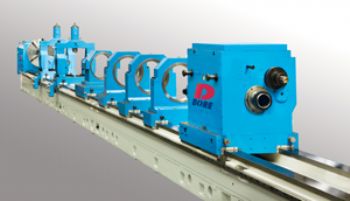

A new generation of high-performance deep-hole boring (DHB) machines has been introduced by Halifax Machine Tool Co Ltd (

www.halifaxmachines.com).

The D-Bore range has been designed to meet the requirements of industry sectors such as oil and gas, aerospace, defence, power generation and steel, where bores are required to extremely close tolerances in components subjected to highly critical applications.

The machines can cut bores up to 300mm in diameter and 20m deep in a range of steels, alloys and super-alloys.

Moreover, counter-boring and trepanning up to 500mm are standard on every machine (depending on the tooling specified); the D-Bore also supports all other DHB technologies, including pull counter boring, skiving, roller burnishing, and skive and burnish, as well as ‘bottle boring’ using the X axis.

Also included in the D-Bore machines are features such as enhanced boring-bar damper technology (based on servo-driven programmable bar dampers) and an ultra-stable cast-iron bed construction for reduced vibration, as well as optimised tool life and accuracy.

D-Bore machines — available in four configurations based on a traditional flat-bed design — can be equipped with either ejector or STS boring systems (STS oil swarf/chip management systems are designed to achieve maximum chip flow and chip removal).

Meanwhile, a choice of CNC systems and graphical user interfaces has been designed to maximise productivity and minimise production costs by providing the optimum performance for all deep-hole boring applications.

Machines in the D-Bore range are custom-built from standard modules to meet a customer’s specific requirements.