Delcam plc (

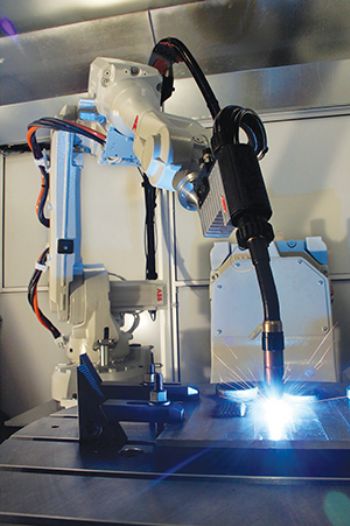

www.delcam.com) has added an ABB robot arm fitted with a Fronius CMT Advanced welding head to the range of manufacturing equipment at its Birmingham site.

This will be used for research into the programming of robots for the additive manufacturing of metal parts with Delcam’s PowerMill Robot software. Fronius developed Cold Metal Transfer welding to join materials with different properties — in particular aluminium and steel.

The process uses high-frequency movement of the wire to give a spatter-free, stable and reproducible deposition of material that Delcam believes could have great potential in metal additive manufacturing.

The ABB robot arm has six axes of movement, with two more — tilt and rotation — provided by the table holding the material. This allows parts to be oriented into the optimum position as they are being built, which enables complex shapes to be created with less need for extra support structures.

PowerMill Robot also makes it as easy to program a robot for machining as it is to program a five-axis machine tool. Users have access to all the multi-axis machining strategies within PowerMill and can use all the system’s project management options to manage, store and retrieve data.

As well as making it possible to program robots for additive manufacturing, PowerMill Robot can be used for tool-to-part applications — especially for machining large parts, such as composite panels that need to be trimmed — or for part-to-tool applications, such as grinding or polishing.