Supplying a niche market at MACH

Posted on 06 Jun 2016. Edited by: John Hunter. Read 3205 times.

MACH 2016

MACH 2016Chris Boraston, managing director of Coventry-based Advanced Grinding Solutions , said: “We supply niche-market high-end grinding and finishing machines and grinding wheels for special applications in what is already a specialist market.

As such, we don’t get — and indeed don’t search for — large numbers of enquiries for general engineering applications. That said, MACH was a success for us; it did not bring us hundreds of enquiries, but it did bring us a sufficient number of very interesting and challenging enquiries that made exhibiting well worthwhile.”

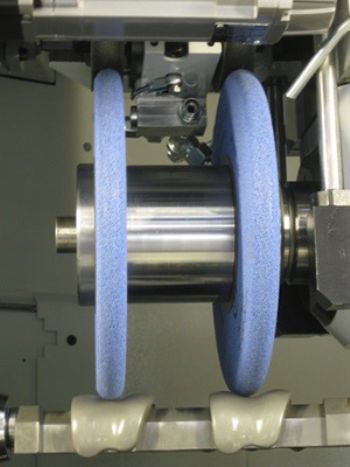

A high level of interest was shown in the newly launched Tschudin 400 Proline centreless grinding machine, which is the first in the world to offer automatic height adjustment of the regulating wheel. This patented feature offers much faster and easier set-ups; it also compensates automatically for any change of grinding geometry caused by wear to both the grinding wheel and control wheel, thereby ensuring that part quality remains consistent throughout long production runs. (

www.advancedgrindingsolutions.co.uk)

The machine also featured Tschudin’s patented moveable work-rest axis (W axis); this allows for additional grinding processes such as the grinding of several parts at a time, or the splitting up of grinding processes in the same cycle — such as both a roughing and finishing operation in one automatic set-up. A high level of interest was also shown in the range of Haas universal grinding machines that AGS sells.

“We received visits from a large number of existing customers in the medical and aerospace industries, including one from the director of a large aerospace company that has a number of machines on order for grinding turbine blades — a Haas speciality. We also reveived several enquiries for the production of artificial knees and hip joints, as well as bone reamers and cutters.”