MACH 2016

MACH 2016 Birmingham-based Delcam (

www.delcam.com) highlighted a new way of machining blisks using a method developed in conjunction with the tooling supplier Technicut.

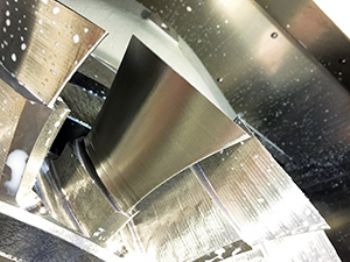

It covers the blisk-machining process from start to finish and combines new tooling concepts with machining strategies in Delcam’s PowerMill CAM software for the rough, semi-finish and finish machining of integrally bladed rotors. The example shown at

MACH was machined in just 35hr — less than half the time that would have been needed using conventional methods.

The initial roughing used a Technicut Titan X-Treme Ripper end mill to produce a series of slotting cuts between the blades; as well as removing the bulk of the material between these, this operation relieves any stresses in the billet resulting from the forging process.

The semi-finishing and finishing operations on the individual blades are then undertaken in a series of vertical sections, working from the tip downwards, with the lower sections left in the rough state to maintain the stiffness of the blade in the area being machined.

In addition to the specific tool-paths for blisk machining in PowerMill, key to the new method is the use of barrel cutters from Technicut for both semi-finishing and finishing.

These tools incorporate a much larger radius on the cutting surface than that on the ball-nose cutters that would normally be used — allowing the same cusp height to be achieved with a step-down up to three- or four-times greater.

This means that fewer cutting passes are needed to achieve the required smoothness.