Critical plastic parts made and supplied by Proto Labs’ Protomold rapid injection moulding service have helped to accelerate the time-to-market of a new drill-less dental treatment. Developed by DMG Dental, the treatment means that a trip to the dentist could soon be a less fearful — and much quieter — experience.

For many people, the high-pitched whir of a dentist’s drill is sufficiently chilling that they would prefer to take chances with their oral hygiene than book an appointment for a routine check-up. However, a brand-new device created by DMG Dental may convince them otherwise.

While most people brush their teeth as part of a daily routine, flossing is an occasional practice at best for many. However, the rather unpleasant truth is that the spaces between the teeth offer the perfect environment for the acidic bacteria that attack tooth enamel minerals. This leads to the development of ‘pores’ in the tooth surface that subsequently give way to decay.

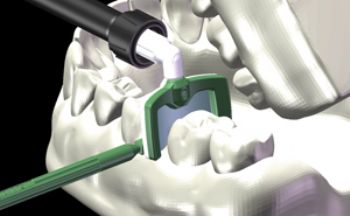

Until now, the only way to treat decay between the teeth was by drilling to reach the cavity and filling — an approach that almost always leads to the loss of a substantial amount of perfectly healthy tooth. However, DMG Dental’s award-winning Icon system addresses acid attack without the use of a drill. The success of this product is based upon the application of plastic inter-dental wedges to separate teeth that are very close-set.

Steffen Effenberger, head of technical development at DMG, says: “It is essential that the dentist has enough space between teeth to complete the entire treatment. Dentists were already using wedges in other procedures, but they were usually made of wood. We couldn’t use wood because it would absorb the materials used in the treatment after tooth separation, so we started the development of an appropriate plastic wedge. ”

Re-inventing the wedge

In essence, DMG had to re-invent the inter-dental wooden wedge. “The challenge was to realise a universal standard wedge that could adequately separate all types of teeth,” says Mr Effenberger. “We started by changing the geometry, creating a trapezoidal shape in cross-section. Initially, we used our own 3-D printer to create about 10 different prototypes, but these were unsuitable for the field tests because they have very different material properties. Tooling would generate additional costs, which for a non-field proven product was too risky — and it would take too long. Then, a colleague discovered another option at a trade show — Protomold, the rapid injection-moulding service from Proto Labs. All we needed to do was upload our 3-D CAD model to the Protomold Web site, and we had an actual production quote in our hand within a day.”

The team at DMG was more than surprised by the speed and reliability of the service it received from Telford-based Proto Labs (www. protolabs.co.uk). Previously, it had been forced to accept prototyping lead-times of more than eight weeks, but this was reduced to two-three weeks with Proto Labs — from initial contact to receiving finished parts.

Mr Effenberger says: “In fact, Proto Labs would have been even faster, but we still had to clarify a few things. For instance, we needed to provide our own material to Proto Labs in order to meet particular medical standards. After that, development accelerated rapidly; and we were chasing responses from dentists so we could improve our inter-dental wedge. For example, we discovered that the ‘comb’ could be omitted entirely, while an arch in the lower part of the wedge made it even more resistant to distortion and provided an optimal fit to gum pockets.”

Four-week development time

After only four weeks of development, the current version was completed at the end of August 2011. The first deliveries have been made, with the initial low-volume batches supplied by Proto Labs while DMG was waiting for the manufacture of steel tooling for full-scale mass production.

“Our existing tool supplier was glad that we had worked with Proto Labs during the prototype stage because it is not set up for frequent modifications or low-volume production,” says Mr Effenberger. “Simply, we wouldn’t have got to market so quickly without Proto Labs.”

So how does Icon work? Once the inter-dental wedge has separated the teeth, the surface of the unhealthy tooth can be pre-treated with a special gel. The area is then dried with alcohol before the Icon resin is applied using a plastic syringe; it penetrates the decay, seals the pores and hardens.

In conclusion, Mr Effenberger says: “In Proto Labs we have found a partner who provides high reliability in order processing. Every deadline was met! In fact, we often did much better than the promised 24hr from uploading the 3-D model, and the manufacturability advice that we received for the realisation of our models was very good.

“For this reason, we have used the company’s Protomold injection-moulding service for making improvements to our syringe applicator. Whenever time is short and we need real parts, we rely on Proto Labs as a partner to develop products faster and better.”

Quick delivery on prototype parts

Proto Labs, whose customers include companies from many industry sectors (including medical, aerospace, automotive and consumer electronics), offers two services.

Protomold is the injection-moulding service. Customers can submit a 3-D CAD model of a part to the Protomold Web-based quoting system (ProtoQuote) and receive a detailed ‘manufacturability’ analysis — as well as an accurate all-in production price — in just hours. Moreover, customers can make last-minute design changes, uploading as many iterations as they need to get the right model, material and cost. Protomold can also deliver injection-moulded prototype and low-volume plastic parts produced from a choice of hundreds of materials — in as little as one business day. Firstcut is Proto Labs’ machining service. Again, customers can submit a 3-D CAD model of a part to the Firstcut web-based quoting system (First-Quote) and receive a detailed manufacturability analysis; they can also upload as many iterations as they need to get the right model, material and cost. Firstcut allows customers to have a fully functional prototype early in the development cycle, and they can choose from a range of over 30 materials (such as ABS, Nylon, PEEK, aluminium and brass). The prototype can be produced in as little as one business day.