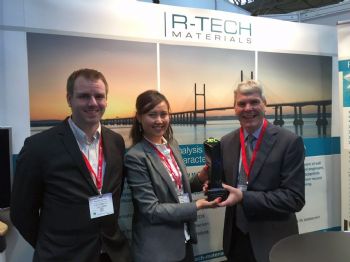

Port Talbot-based R-Tech Materials — one of the UK’s leading testing, analysis and consultancy businesses — has hailed

Advanced Engineering 2017 at the NEC a huge success after seeing a 350% increase in visitors to its stand and receiving 11 firm enquiries (

www.r-techmaterials.com).

The company’s experienced team of engineers, metallurgists, materials scientists and chemists help manufacturers with material approval and characterisation, identify quality issues, solve processing problems and identify why a product has failed.

During the show, it was presented with its

JEC Asia Innovation award (via a video link) for its work on developing an early-warning safety sensor for hydrogen fuel-cell storage tanks in cars.

Standard tests carried out by R-Tech include lap shear, in-plane shear, climbing drum peel, shore hardness, compression of core materials and shear properties of sandwich panels, as well as fatigue testing (in tension or in bending) at loads of up to 100kN.

The company can also offer bespoke testing thanks to its bi-axial extensometry, in-house machine shop and strain-gauging capabilities.

Operating in a wide range of industries, including aerospace, marine and automotive, R-Tech is accredited to perform testing in tension, compression, flexure, shear and hardness to ISO and ASTM standards under controlled temperature and humidity conditions.

It can also prepare laminates, where required. It is on track to secure aerospace approval from Nadcap in the near future, and it has teamed up with Zwick Roell to run training courses on the mechanical testing of composites in 2018.