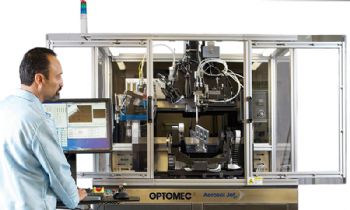

Optomec (

www.optomec.com), a US-based global supplier of production-grade additive-manufacturing systems for 3-D printed electronics and 3-D printed metals, confirms that its Aerosol Jet technology is being used by Carnegie Mellon University’s College ofEngineering (in Pittsburgh, Pennsylvania) to develop 3-D micro-additive manufacturing methods for fully printed conformal sensors, ‘low-loss passives’ and antennas for on-chip and off-chip electronics.

Carnegie Mellon’s Advanced Manufacturing and Materials Laboratory, led by Rahul Panat, is working on solving fundamental and applied problems in the areas of printed and flexible microelectronics manufacturing and lithium-ion batteries — areas that are particularly relevant to the development of devices and systems for ‘wearable’ and Internet of Things applications.

Examples include ‘smart’ contact lenses, wearable electronic clothing, robotic skins and ‘bio patches’.

Dr Panat said: “We are using an Optomec Aerosol Jet 3-D print system to directly print nano-particle inks and polymers over complex surfaces.

"This system has enabled us to fully print 3-D antennas at the sub-100um length scale and to conduct simulation studies to identify omnidirectional antenna designs.

"These unique fabrication methods can pave the way for several applications in the area of high-speed communication.”