GE Aviation (

www.geaviation.com) is about to begin certification testing of its newest turboprop engine — the Catalyst.

Engine testing is proceeding as planned, and GE engineers have run the engine for 60hr since December, advancing from idle to full-power testing this spring and generating critical data on the engine.

Component certification testing is imminent; it will be followed by engine certification testing.

The first test engine is currently installed in an 800-channel test rig at the Czech Technical University’s Centre of Aerospace and Space Technology in Prague.

GE Aviation’s Brad Mottier said: “The engine is running well, and the hardware looks great. Performance is at or above expectations.

"We look forward to altitude and ingestion tests, which will kick off our certification programme.”

Assembly work on the second Catalyst is near completion, and the engine is scheduled to run this summer. It will be sent to Canada later this year for altitude testing.

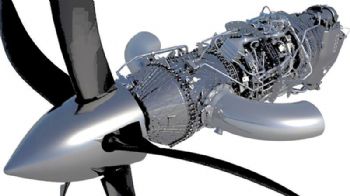

The Catalyst is the first all-new ‘clean-sheet’ engine in more than 30 years in the BGA (business general aviation) market.

The 1,240shp-rated engine is part of GE’s family of turboprop engines aimed at BGA aircraft in the 1,000-1,600shp range.

The engine features an industry-best 16:1 overall pressure ratio, enabling it to achieve a fuel burn as much as 20% lower than — and a cruise power 10% higher than — competitor offerings in the same size class; and at 4,000hr, it offers 33% more time between overhauls than its leading competitor.

The Catalyst engine also includes more 3-D printed components “than any production engine in aviation history”.

A total of 855 conventionally manufactured parts has been reduced to 12 ‘additive’ parts, including sumps, bearing housings, frames, exhaust case, combustor liner, heat exchangers and stationary ‘flow path’ components.

‘Additive’ components reduce the Catalyst’s weight by 5%, while contributing a 1% improvement in specific fuel consumption.

The engine will power Textron Aviation’s new Cessna Denali. By the time the Denali enters service in 2020, the engine will have completed more than 2,000hr of testing.