MELD Manufacturing Corporation’s patented MELD technology has been selected by the US Army to be part of its inaugural Army Expeditionary Technology Search, based on its proposed use to create lighter-weight higher-strength materials for next-generation combat vehicles.

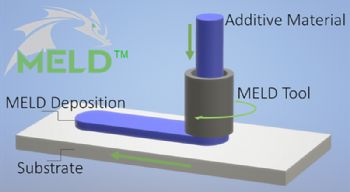

MELD additive-manufacturing manager Chase Cox said: “MELD technology is ideal for combat vehicles because it allows the use of unweldable metals and can create, join, coat or repair a wide range of metallic materials that offer superior strength and corrosion-resistance without adding weight.

"Additionally, MELD machines do not require a laboratory environment for operation and are highly scalable, making them perfect for implementation on the battlefield. Being able to repair parts or manufacture components on demand ‘in theatre’ would both increase efficiency and save both time and money.”

Mr Cox said: “What sets us apart from other technologies is that we aren’t melting. When you melt, you introduce weakness and other issues.

“By taking the material up to a point where it is malleable but not melted, we end up with properties that meet or exceed similar processes and — in some cases — even those of the original material.”

While there are other AM processes that do not require melting of the feedstock material, MELD is said to be further differentiated by the fact that it is an open-atmosphere process; no special chambers or vacuums are needed to operate a MELD machine.

Moreover, as well as being used to additively manufacture components, the MELD process can be used to repair, coat and join materials — and could make it possible to weld previously unweldable materials.

The MELD process is said to deposit material at least 10-times faster than fusion-based metal AM processes.

It is expected to find application in a range of areas, including the automotive, aerospace, defence and turbo-machinery industries.