Germany-based Gehring (

www.gehring-group.com) is to equip Volkswagen Group (VW) factories in North America and China with the latest laser and honing technology for the production of coated EA 211 evo 1.5-litre four-cylinder turbocharged engines.

Gehring is a leader in the field of cylinder machining to increase the efficiency of internal-combustion engines. The VW engine has been equipped with the latest technologies to increase its efficiency.

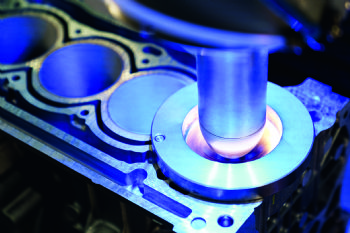

The thermal coating of cylinder bores is a sought-after technology for increasing the efficiency of internal-combustion engines.

In order to produce a strong bond between the coating and the engine block, efficient laser roughening processes are required to ensure overall functionality.

Apart from cost savings and a better working environment, the overall engine design is improved.

In addition to high-adhesive tensile strengths with low roughness, economic advantages are realised in series production, since no wearing tools are needed and coating material is saved.

Both aluminium and cast iron can be pre-machined with the laser refining process.

The Gehring laser roughening machines have two spindles, with innovative rotation optics, for the simultaneous machining of two cylinder liners.

The process leads to low-friction and wear-resistant cylinder liners, which contribute to more-compact and more-efficient internal-combustion engines.