Northwestern University researchers in the USA have developed a new 3-D printer that is so large and quick it can print an object the size of an adult human in a few hours.

Called HARP (high-area rapid printing), the new technology can be used to manufacture products on demand.

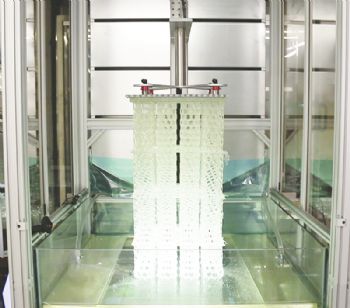

The prototype is 13ft tall with a 2.5ft

2 print bed and can print about 1.5ft in an hour — a record throughput in the 3-D printing world. It can produce single large parts or many different small parts at the same time.

Over the last 30 years, the pursuit of larger parts via 3-D printing has often come at the cost of speed, throughput and resolution, but HARP can compete with traditional manufacturing techniques in terms of resolution and throughput.

Chad Mirkin, who led the development of HARP at Northwestern University (

www.northwestern.edu), said: “3-D printing is conceptually powerful but has been limited practically.

“If we could print fast without limitations on materials and size, we could revolutionise manufacturing; HARP is poised to do that.”

The system uses a new — and patent-pending — version of stereolithography, which converts liquid plastic into solid objects.

It prints vertically and uses projected ultra-violet light to cure the liquid resins, producing items that are hard, elastic or even ceramic. They are mechanically robust and can be used in many applications, including as parts for cars, aircraft, dentistry and orthotics.

Every resin-based 3-D printer generates a lot of heat when running at high speed; the HARP technology overcomes this problem with a non-stick liquid that behaves like liquid Teflon.

It projects UV light through a window to solidify the liquid on a vertically moving plate; the liquid Teflon flows over the window to remove heat.

Mr Mirkin concluded: “When you can print fast and large, it can really change the way you think about manufacturing.

“With HARP, you can build anything you want — without moulds and without a warehouse full of parts.”