A free evaluation licence from Alphacam (

www.alphacam.com) meant that a manufacturer could start producing essential PPE for front-line health workers, using a machine tool that had not been fully commissioned and was standing idle during the COVID-19 crisis.

Codem Composites had recently bought a pre-owned Blackman & White CNC machine for cutting carbon-fibre pre-impregnated with epoxy resin, to make components for the motor-sport industry and satellite dishes.

Managing director Kevin Doherty said: “It hadn’t been fully commissioned, and we had post-processing issues with the software and interface. We didn’t want to invest several thousand pounds in software immediately, given the uncertainty brought about by COVID-19, but when we got the call asking for help in cutting NHS scrubs, we approached Alphacam — part of the Hexagon group — to help us get the machine up and running.

“We had already discussed switching our CAD/CAM to products from Hexagon’s Manufacturing Intelligence division when we need to review our existing licences, and we are also in the early stages of looking at investing in an ERP system from them. Alphacam supported us by giving a free evaluation licence for us to cut the scrubs.

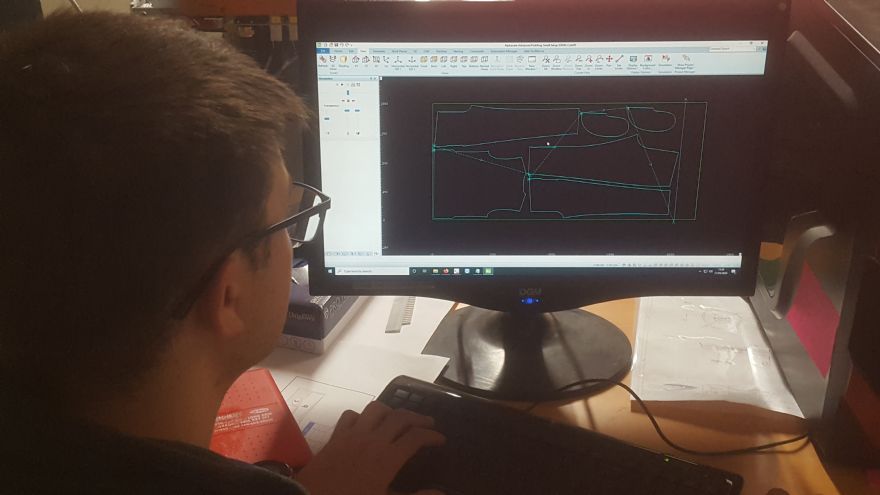

“A full scrub comprises several components, and it comes in a variety of sizes, ranging from small to double XL. The tunic is made from a front, a back, sleeves, a collar, a V at the front and a couple of pockets. The trousers are a left and right leg both front and back, two standard pockets on the side and a patch pocket on the back.

“To use the material properly and avoid waste, we may nest a number of left legs, for example, together with tunic fronts or collars and sleeves.”

Running at a capacity of around 500 full scrubs a week, the Blackman & White machine cuts components for a group of volunteers in Northamptonshire to put together.

“Previously, they had been cutting parts by hand; with us taking on the cutting, they can now spend more time sewing.”