Represented in the UK by Tamworth-based specialist tool supplier Industrial Tooling Corporation (ITC —

www.itc-ltd.co.uk), the BIG Kaiser brand is renowned for its quality, precision and innovation. The Swiss-based company has taken this to a new level with its new EWA fully automatic fine boring tool which has won the ‘production performance’ category in the Global Industry Awards 2020.

Entered for the award by Boulland DPM, BIG Kaiser’s partner in France, the production performance category highlights innovations focusing on the significant improvement of key metrics or performance through productivity gains.

Giampaolo Roccatello, BIG Kaiser head of sales and marketing, said: “We congratulate and thank Boulland DPM, and are delighted that the EWA and its pioneering role towards Industry 4.0 implementation has been recognised with this prestigious award.”

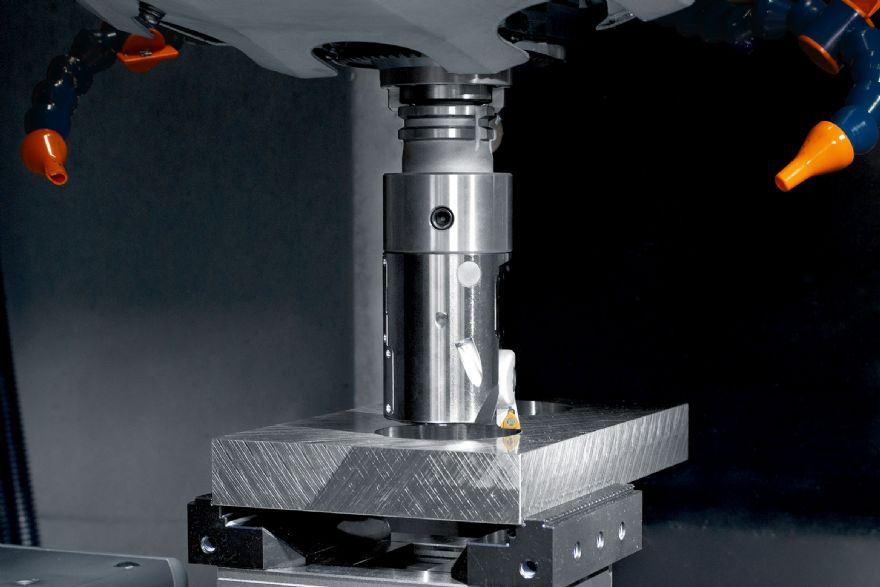

The EWA is an intelligent fully automatic fine boring tool that does not require human intervention. It achieves fast, accurate boring as the process does not need to be stopped to check measurements or manually adjust the fine boring tool. As well as saving time, this minimises costly scrap resulting from manual adjustment errors.

The new EWA features a powerful motor for robustness and reliability that is sealed against dirt and water in accordance with IP69. The clamping system provides additional stability and repeatability to deliver consistently high reliability and precision at cutting speeds above 200m/min.

Jose Fenollosa, BIG Kaiser head of R&D, said: “The EWA is far ahead of the rest in its level of automation and sophistication. This gives our customers real benefits in terms of time and money saved and this makes it ideal for Industry 4.0 applications. We are talking to potential customers now, including some of the leading machine tool manufacturerst — the EWA product will be widely available in 2020.”

The EWA can be used in three primary configurations and this includes tablet, PC and fully integrated control systems and features wireless connectivity to BIG Kaiser’s user-friendly smartphone and tablet app for easier tool monitoring and configuration. It can also automatically communicate with a pre-setter, so diameter measurements can be transferred without operator intervention via a tablet or app-enabled device.

For legacy machine tools, a PC interface between the machine tool and the EWA can be used to provide a fully-automated, closed-loop control cycle. This is suitable for instances where commands are sent from the machine tool to the EWA, as the system can automatically adjust or stop the machining process as and when required.

For the next generation of machine tools, the BIG Kaiser EWA control software can offer a fully integrated system whereby the system will run directly on the machine tool itself to provide an equivalent level of automatic control, requiring no external control device.

At

EMO 2019, the EWA was demonstrated working with a Fanuc CNC machine with the entire boring cycle performed automatically — the configuration was undertaking initial boring, then measuring it and then adjusting the tool to complete the final precision bore.

The new EWA will initially be available in two variants; the EWA peripheric will cover diameters from 68 to 90mm with the EWA centric developed for smaller bores from 10 to 54mm. Further models for different adjustment levels and diameter ranges are currently in the design phase and will be unveiled soon.

The EWA can be used with BIG Kaiser’s extensive range of accessories, making it easy to add to an existing system. To maximise flexibility, the EWA 68 model offers an adjustment range of 22mm, which is substantially larger than similar solutions available.

The EWA also has an integrated accelerometer that measures vibration during the cutting process and in the event of excessive vibrations, it alerts the machine tool to automatically adjust its cutting parameters accordingly.

The EWA 68 with tablet control is expected to be available for sale in mid-2020 and ITC will be updating customers as soon as it is available in the UK.