Essex-based

www.guhring.co.uk Xcel Aerospace is a sub-contract manufacturer that offers a range of services that include CNC machining, fabrication, assembly, additive manufacturing and kitting— plus its own range of braided leads. The company works closely with the likes of Rolls-Royce, Collins Aerospace, Safran, Bombardier, ITP Aero, Marshall and Incora.

To retain its position as a key supplier, and to ensure cost-effective manufacturing, the company recently invited Birmingham based tooling manufacturer Guhring (

www.guhring.co.uk) to review the machining process on an aerospace valve component made from cast aluminium with a 9% silicon content.

The solid-carbide Woodruff cutter historically used had three teeth on a 21.7mm diameter; and although expensive, it had a relatively poor tool life, cutting 10 components before tool replacement was required. The abrasive high-silicone content aluminium was creating productivity, cost and surface finish issues.

Dewar McKinlay, Guhring’s regional sales manager, said: “We have a new method of manufacturing PCD tools by printing them on a MarkForged Metal X 3-D printing machine. This approach to manufacturing not only gives us short lead times but also design flexibility, as we can any tool design we need.

“We first printed a plastic tool to demonstrate the 3-D printing concept tool to the customer. This was followed by a three-flute tool that was similar to the current tool but with brazed PCD tips; and although these lasted considerably longer than the previous tool we wanted to go further.”

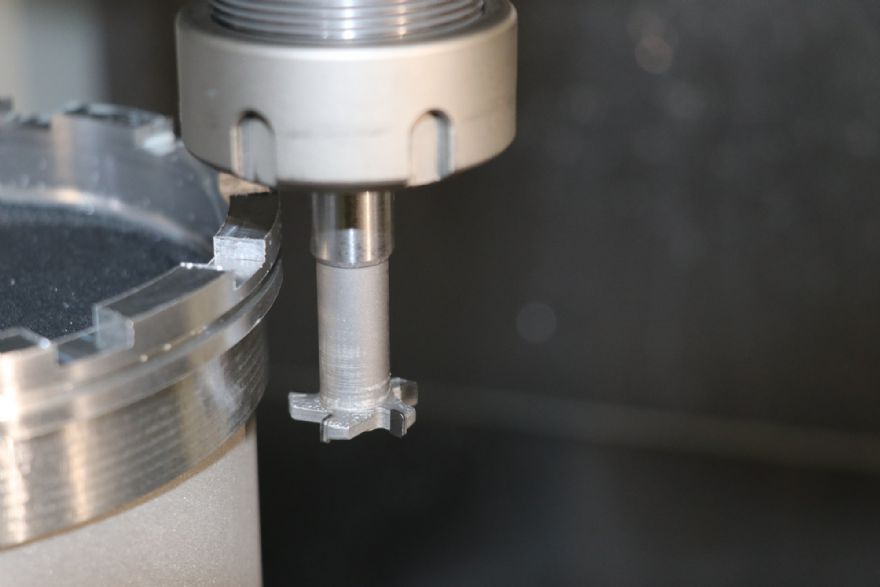

The design flexibility Guhring now has with its 3-D printing facility, supplied by Mark3D UK Ltd, enabled the company’s engineers to develop an optimised design within a matter of weeks. The new design increased the number of cutting edges from three to five, allowing Excel to increase the feed rate to significantly reduce production times while extending tool life.

Manufactured from H13 tool steel, the tool body of the 3-D printed Woodruff cutter has a 13mm-diameter shank with a 70mm overall length and the identical 21.7mm diameter at the cutting edge.

Mr McKinlay added: “This aerospace part is a long-running project for Excel and we have increased tool life beyond all expectation. The previous solid-carbide tool quickly wore and required a change-over after 10 parts; with our new 3-D printed PCD Woodruff cutter we have machined more than 180 parts — and it is still performing well.

“This is giving the customer a significant tool cost saving while reducing the down-time and inconvenience of change-overs.”