Sandvik

Sandvik and

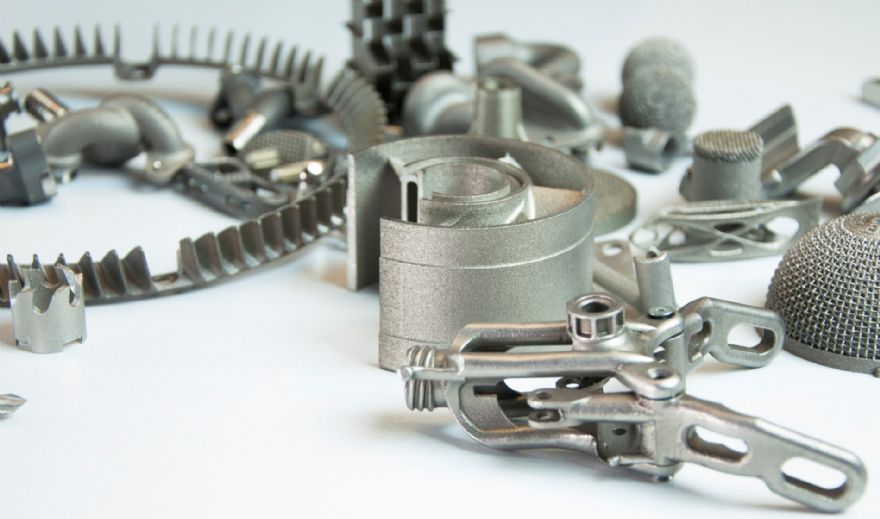

Beamit have made several important advances in metal additive manufacturing (AM) over the last six months. Most recently the Beamit Group acquired ZARE, resulting in two leading AM service bureaus in Europe joining forces to become one of the largest independent AM service providers.

In July 2019, Sandvik acquired a significant stake in Beamit, which supplies AM components to industries that include aerospace, space, automotive and energy. The company complements Sandvik’s additive manufacturing offering, which includes a comprehensive range of metal powders for AM and leading expertise across the entire AM value chain.

Founded in 1963, ZARE has grown to become a leading, integrated AM service bureau offering a full range of services. The quality-certified company has around 50 employees, a wide range of metal and polymer printers, as well as CNC machines for post-processing operations.

Its merger with Beamit has resulted in an AM organisation, employing more than 100 people, with five facilities in an area between Parma and Reggio Emilia in Italy — plus four ‘commercial offices’ in France, Germany, the UK and Japan.

Beamit and ZARE will continue to operate under their respective brand names, although activities will be consolidated under the Beamit Group.

Beamit’s acquisition of ZARE follows its recent investment in PRES-X, which specialises in AM post-processing and offers high-pressure heat treatments for 3-D printed production parts, along with other post-processing methods such as smoothening external and internal surfaces and depowdering.

Furthermore, Sandvik has recently ‘commercialised’ a new powder plant for the company’s Osprey titanium- and nickel-based super alloys, which means that it now offers ‘the widest range of AM alloys on the market’.

The new plant is certified to ‘AS9100 Revision D’ for deliveries to the aerospace industry, as well as the ‘ISO 13485:2016’ certification for deliveries to the medical sector.

Sandvik’s UK powder production facility in Neath has also recently been awarded the ‘AS9100D’ certification.