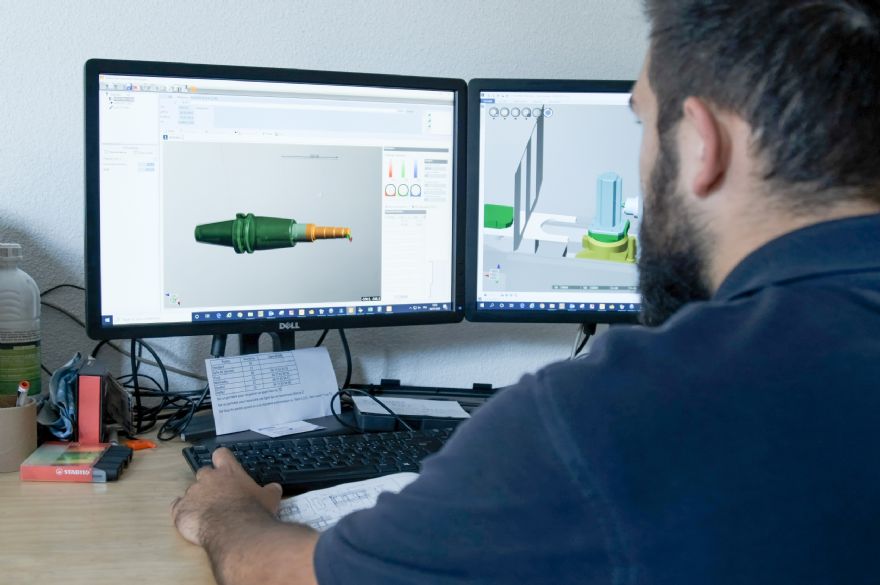

A combination of tool-path simulation for G-code verification and cutting tool management are significantly improving productivity for a company specialising in machining hydraulic blocks.

Based at Saint-Germain-Laval in central France, Evaflo uses (

NCSimul’s) machine simulation module from the

Hexagon group to help create a complete digital chain, from receiving a customer’s product plans through to setting up a CNC machine tool for cutting the prototype.

The Botellé brothers — Élysé, Valéry and Floréal — were born into the machining industry, learning from their father, who focused on milling. When they acquired a machine shop in 2000, they continuously improved their production performance, and today about 80% of their income now comes from machining hydraulic blocks used in hydraulic circuits.

The brothers originally undertook programming using a mix of basic CAM and code written manually using a text editor. Élysé Botellé said: “However, checking the code line by line on the machine was time-consuming, so we invested in simulation software that would validate the checking stage. Installing the NCSimul Machine module cut the time taken to complete that task by a factor of three.

“Having saved that time in the workshop, we then turned our attention to improving productivity in the office, developing our own code generator, dedicated to producing machining tool-path programs for our five Mori Seiki four-axis machining centres and two Mori Seiki CNC turning machines, which we simulated in the digital twin created by NCSimul Machine.

“This detects programming errors and any potential collisions from the same NC G-code that actually drives the machine tool, so we were guaranteed absolute accuracy before starting to cut metal.”

Based on the ‘real characteristics’ of Evaflo’s machines, NCSimul is providing the company with a dynamic verification solution.

Moreover, the software has complete synergy with NCSimul Tool, which ‘integrates the brother’s digital tools into the global production process’, optimising the tool cycle using simplified import functions and pre-configured master models.