ExOne

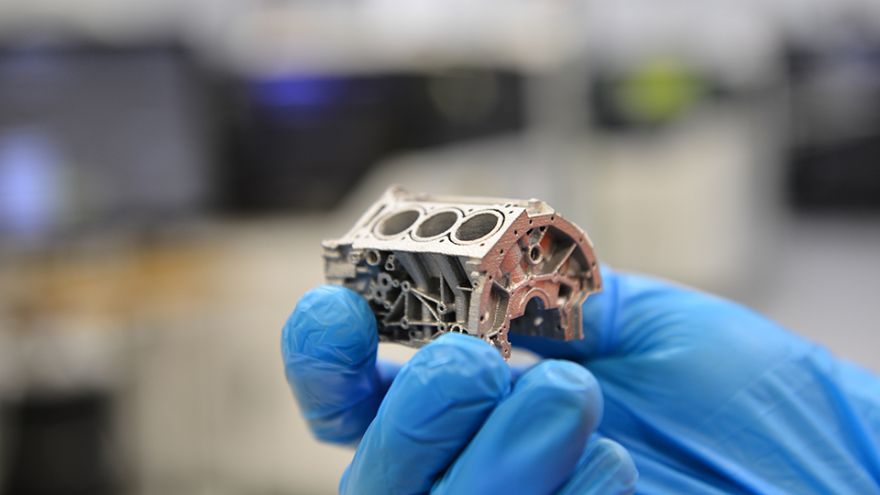

ExOne, a global leader in industrial sand and metal 3-D printers using binder jetting technology, has confirmed that aluminum alloy 6061 is now a ‘customer-qualified’ material in collaboration with

Ford Motor Co.

A new patent-pending process to binder jet 3-D print and sinter the material delivers rapid and repeatable results with a 99% density and material properties comparable to die casting. Additional collaborative and individual patents are expected to be filed by Ford and ExOne.

Rick Lucas, ExOne’s chief technology officer, said: “There has been skepticism for years that binder jet 3-D printing and sintering of aluminium was even possible. Manufacturers in other technology areas have struggled to deliver a commercially viable solution in this area for more than a decade, but we take pride in collaborating with our customers to solve the toughest challenges.

“We believe this innovation will help deliver lighter products and sustainability benefits that will have a sweeping impact across a wide range of products.”

To date, ExOne has ‘qualified’ 23 metal, ceramic and sand materials for use on its industrial binder jetting printers. With the addition of aluminium, that now includes 12 single-alloy metals. Titanium is now being fast-tracked for qualification in partnership with a global medical device company.

Because ExOne technology can 3-D print almost any powder, the company has a tiered material qualification system to signify the varying levels of material property results that parts 3-D printed with its technology will deliver.

These levels help manufacturing customers understand whether ExOne binder jetting technology could meet their specific application needs.

Binder jetting is a 3-D printing process that uses a digital file to quickly inkjet a binder into a bed of powder particles — metal, sand or ceramic — creating a solid part one layer at a time. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object.

ExOne’s qualification of aluminium in collaboration with Ford is the result of a new patent-pending process for binder jet 3-D printing and sintering. Moreover, the end product is being accomplished without excessive levels of liquid-phase sintering that leads to melting and distortion.